401 Ryland St. Ste 200-A,

Reno, NV 89502

United States

E-mail: sales@albmaterials.com

- DY8X8 Neodymium Magnets, 2 1/2 inch dia. x 1 1/2 inch thick

- DF01 Neodymium Magnets, 15/16 inch dia. x 1/32 inch thick

- SBX0X06-OUT Neodymium Magnets, 1 inch length x 1 inch width x 3/8 inch thick, with step OUT

- D-D12.7H6.35X/16 Neodymium Magnet, 12.7x6.35mm Disc Magnet

- B40x15x5mm Neodymium Magnet, 40 x 15 x 5mm Block Magnet

- DB6 Neodymium Magnets, 11/16 inch dia. x 3/8 inch thick

- DDX4 Neodymium Magnets, 13/16 inch dia. x 1 1/4 inch thick

- BY0Y0X0-N52 Neodymium Magnets, 2 inch x 2 inch x 1 inch thick

- Round Magnetic Separator Rods

- DX8X0 Neodymium Magnets, 1 1/2 inch dia. x 1 inch thick

- MM-B-32 Metric Mounting Magnets

- DX23 Neodymium Magnets, 1 1/8 inch dia. x 3/16 inch thick

- B80x20x2mm Neodymium Magnet, 80 x 20 x 2mm Block Magnet

- D2C Neodymium Magnets, 1/8 inch dia. x 3/4 inch thick

- D-D15H7-N35H Neodymium Magnet, 15x7mm Disc Magnet

- B15x5x5mm Neodymium Magnet, 15 x 5 x 5mm Block Magnet

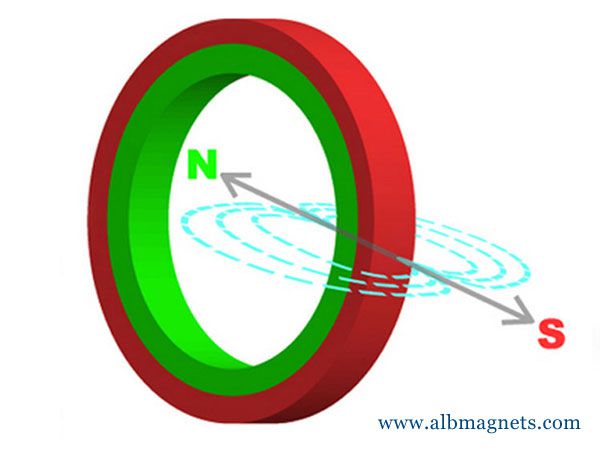

Radially Oriented Ring Magnet

radially oriented ring magnet

Radially oriented, anisotropic Nd-Fe-B ring magnets ·, Unlike sintering, this process does not rely on a magnetic field for radial orientation.

Radially oriented, anisotropic Nd-Fe-B ring magnets (ALB-DR)

Daido has developed a unique hot extrusion process to produce radially oriented anisotropic Nd-Fe-B ring magnets, ALB-DR.

Unlike sintering, this process does not rely on a magnetic field for radial orientation.

Our process starts with raw material powders manufactured by rapid quenching of the prescribed alloys into nanocrystalline flakes.

These flakes are hot-pressed to the theoretical density and then hot extruded to ring-shaped magnets.

During this advanced hot extrusion process, randomly oriented crystal grains go through preferential grain growth and rotation.

This results in the full-density, nanocrystalline structure with the highest level of radial orientation.

Although the basic magnetic properties (Br, Hc, and (BH)max) are similar to sintered Nd-Fe-B, our unique process gives rise to several remarkable features listed below.

Features of ALB-DR

Highest energy product of 240 ~ 400 kJ/m3 (30 ~ 40 MGOe) in the truly radial direction.

Full rings with a wide range of diameters (min. OD 6 mm -) and lengths (max. 80 mm) for easy assembly.

Various magnetization patterns possible (multi-pole to uni-pole, various skew angles) by the design of magnetizing fixtures.

Precise magnetization waveform control (such as rectangular, trapezoidal, sinusoidal) for high power or low cogging.

High heat resistant grades (up to 180 deg. C) available.

Inherently better corrosion resistance due to the absence of internal porosity.

Applications of ALB-DR

- EPS (Electric Power Steering) motors: Combined with controlled magnetization waveforms, ALB-DR can realize quiet and smooth rotation, giving rise to a natural feeling of steering an automobile.

Servomotors: High power and low cogging, quiet and smooth rotation, ideal for AC/DC servo motors used in industrial robots requiring quick and accurate movements.

The electrical power steering motor

AC servo-motor

The manufacturing process of ALB-DR

Realizing close theoretical density and high radial orientation ratio by hot extrusion technology keeping miro structure of grain size.

At ALB Magnets, we sell Neodymium magnets and assemblies because there simply is no stronger type of magnet.

We are best known for our vast inventory along with our phenomenal pricing and customer service.

We welcome the opportunity to problem-solve even the most difficult magnet/contact applications.

Contact us today and put our expertise to work.

radial ring magnet

The manufacture of anisotropic radially magnetized arcs and rings is significantly different from the production of diametrically magnetized rings and arcs.

Radially aligned and magnetized anisotropic arcs and rings are only possible in fully dense sintered NdFeB and need a dedicated press tool and magnetizing fixture and have a limited physical envelope (Max OD 85mm).

Another true radial alignment is possible in all isotropic magnet materials, using both bonded and sintered structures.

Figure 1: Diametric arc magnet cut from a single large block

The majority of permanent magnets are produced with a single direction of magnetization where the lines of flux within the magnetic material are parallel (e.g. axially magnetized disc and rod magnets, block magnets).

Arcs are cut from blocks of manufactured magnetic material.

Note the standard direction of magnetization, as shown by the arrows in figure 1.

This direction is fixed into the structure during the manufacture of the block (the block is pressed to shape in the presence of an external magnetic field that is produced by a solenoid surrounding the block).

This method is standard practice.

The cut arc, therefore, shares the same direction of magnetization as the block.

Figure 2: Arc magnet cut from a single large block

In figure 1, the arc has been cut so that the direction of magnetization of the magnet is parallel to the line of symmetry of the magnet.

This is defined as ‘diametrically magnetized’.

The standard direction of magnetization within such cut arcs is diametrically magnetized.

If the arc was rotated around by a defined angle, the direction of magnetization is also rotated around by the same defined angle, as shown in figure 2.

This is particularly useful for designs such as Halbach Arrays.

True Radial Arcs and Rings

Figure 3: True Radial Arc

As previously highlighted, true radial arcs and rings either require tooling to produce or may not be possible because of the size requirements of the system.

For very low volume prototypes and where the size needed is larger than the tooling can produce, then the best option to create a radial field in large arcs or in rings is to utilize a high number of very small angle arcs.

As before, when considering the complete system, assembling 360 magnets at a 1-degree arc is considerably more difficult than a single ring.

The alternative to a pure field created by 1-degree arcs is to use larger diametrically magnetized arcs to replicate a radially magnetized arc or ring.

Hence the name Pseudo Radial as there is now a significant difference in the ultimate magnet field generated.

Making Pseudo Radial Arcs and Rings from large angle diametrically magnetized arcs

Figure 4: Pseudo Radial Arc from large

angle diametrically magnetized arcs

When using diametrically magnetized arc segments of large angle, a magnetic pattern in the completed arc and ring starts to mimic the desired radial pattern.

The effect may be cruder if large-angle arcs are used but assembly time is relatively fast.

Forty-degree arcs are shown in figure 4.

Making Pseudo Radial Arcs and Rings from small-angle diametrically magnetized arcs

Figure 5: Pseudo Radial Arc from small

angle diametrically magnetized arcs

When using diametrically magnetized arc segments of small angle, a magnetic pattern in the completed arc and ring starts to mimic more closely the desired radial pattern.

The effect may be improved if even smaller angle arcs are used, although this increases the assembly time.

Despite not producing a perfect radial pattern, the finished arc meets the specification requirements for the application.

Twenty-degree arcs are shown in figure 5.

If a pure radial array is required multiple rings stacked axially with each ring being rotated relative to the next can improve the pseudo-radial magnetic wave-shape even further.

Special use of arc magnets – the Halbach Array

Figure 6: Halbach Array

When using arcs where the direction of magnetization is set to different angles, a Halbach Array can be produced, giving a highly uniform (homogeneous) magnetic field in the air gap.

The field strength in the air gap can also be very large (e.g. over 1 Tesla / 10000 Gauss).

Bunting utilizes this technology to produce bespoke Halbach arrays based upon a number of key criteria including:

Outer diameter;

Radially Oriented NdFeB Ring Magnets

Radially oriented neodymium iron boron (NdFeB) ring magnets are state-of-the-

art ring magnets with diverse magnetization patterns in the radial direction.

Radially Oriented NdFeB Ring Magnets

>> Applications of Radially Oriented NdFeB Ring Magnets

1. Servo motors,

Neodymium Anisotropic Sintered Ring Magnet

Optional magnetization, including free multiple magnetizations, skew-type magnetization possible (Radial anisotropic magnet);

1.Single motor for HDDs, FDDs

2.Servomotor for robots, machinery

3.Electrical motors for power steering in automobiles, etc.

4.Actuators

1.The cylindrical shape enables higher precision in external dimensions.

2.As a rotor can achieve uniform magnetic density flux distribution.

3.Fastening the magnet is simple, enabling assembly-related cost reductions.

4.Highly reliable due to enabling rotor construction from a single magnet.

5.Optional magnetization, including free multiple magnetizations, skew-type magnetization possible (Radial anisotropic magnet)

6.Can obtain sine surface inductive flux distribution (multi-pole oriented magnet)

Part of the content in this article is reproduced from other media for the purpose of transmitting more information and does not mean that this website agrees with its views or confirms the authenticity of its content. It shall not bear direct responsibility and joint liability for the infringement of such works.

If there is any infringement, bad information, error correction, and other issues in the content of this page, please contact us at info@albmaterials.com

Link to this article: https://www.albmagnets.com/blog/radially-oriented-ring-magnet.html

How to choose and buy a strong neodymium magnet? ALBMagnets is a professional company for strong magnet design and manufacturing,

providing you with reliable N35, N38, N42, N52, N42SH and other grade super neodymium magnets and SmCo rare earth magnets.