401 Ryland St. Ste 200-A,

Reno, NV 89502

United States

E-mail: sales@albmaterials.com

- BX8C1 Neodymium Magnets, 1 1/2 inch x 3/4 inch x 1/16 inch thick

- D-D25H2.5-N38 Neodymium Magnet, 25x2.5mm Disc Magnet

- DC01 Neodymium Magnets, 3/4 inch dia. x 1/32 inch thick

- BY08Y0 Neodymium Magnets, 2 inch x 1/2 inch x 2 inch thick

- B15x8x4mm Neodymium Magnet, 15 x 8 x 4mm Block Magnet

- DF8 Neodymium Magnets, 15/16 inch dia. x 1/2 inch thick

- D15x2mm Neodymium Magnet, 15 x 2mm Disc Magnet

- R211 Neodymium Magnets, 1/8 inch od x 1/16 inch id x 1/16 inch thick

- D2x5mm Neodymium Magnet, 2 x 5mm Cylinder Magnet

- DAH2 Neodymium Magnets, 5/8 inch dia. x 2/10 inch thick

- B15x10x2mm Neodymium Magnet, 15 x 10 x 2mm Block Magnet

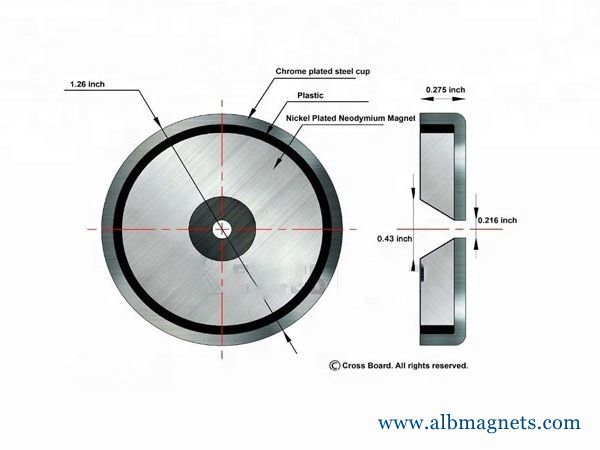

- SC Neodymium Magnets, 3/4 inch diameter

- RA22CS-P Neodymium Magnets, 5/8 inch od x 1/8 inch thick with countersunk hole for #6 screw

- B20x4x3mm Neodymium Magnet, 20 x 4 x 3mm Block Magnet

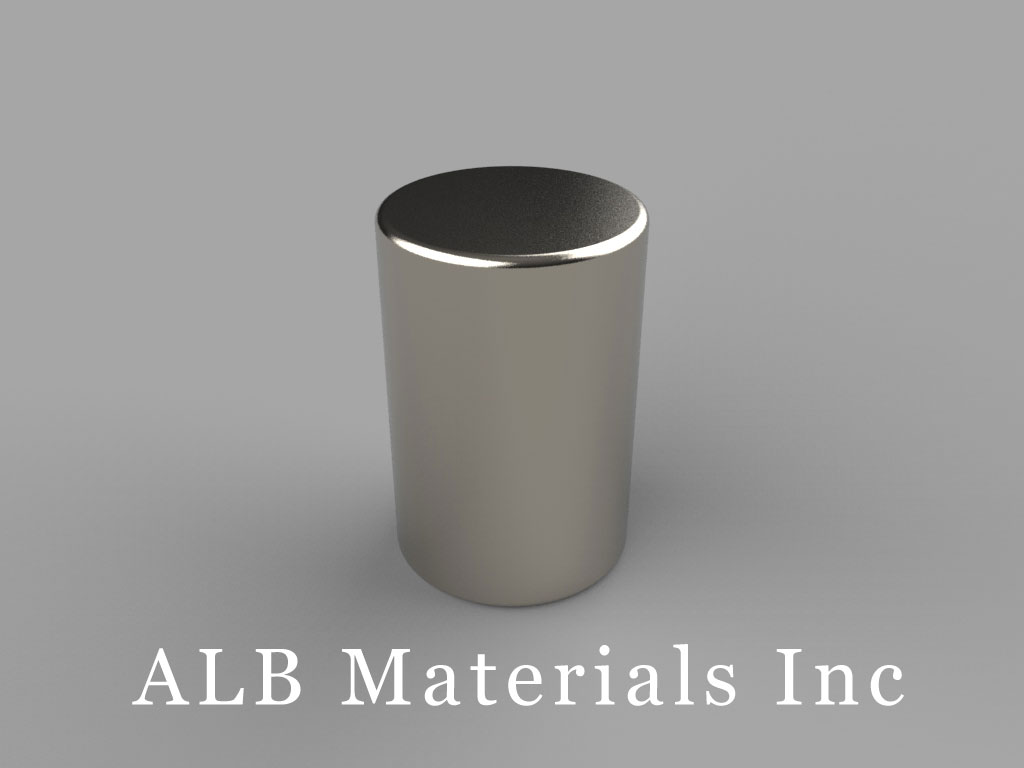

- D4A Neodymium Magnets, 1/4 inch dia. x 5/8 inch thick

- BX841 Neodymium Magnets, 1 1/2 inch x 1/4 inch x 1/16 inch thick

Neodymium N52 Permanent Magnets With Countersunk Holes

neodymium magnets with countersunk holes

Rare Earth Neodymium Block & Bar Magnets with Countersunk Holes

Neodymium Block Cube Magnet with Countersunk Hole ... Also, the countersunk holes these magnets feature make affixing them in place as needed no issue at ...

ALB Magnets cube, block, and bar magnets are crafted from the highest quality rare earth neodymium.

These magnets are utilized across a wide spectrum of industries for a multitude of uses.

To ensure longevity and maximum protection from corrosion, these magnets come triple coated with a base and top finish layer of nickel, with a layer of copper in between.

Also, the countersunk holes these magnets feature make affixing them in place as needed no issue at all.

neodymium n52

N52 Disc Neodymium Magnet 25mm dia x 10mm 1000pcs pack

Industrial strength, large sized, thick disc, high grade, N52 rare earth magnets with extraordinary power.

Not suitable for normal home use due to strong magnetic field, can cause serious injury if not properly handled.

Serious Warning!!!

– Never, ever leave a neodymium magnet of this size unattended especially in the presence of children.

– Separating 2 pieces of such magnets require a great deal of effort.

Hence, do not attach 2 pieces together without at least 2mm of plastic or solid non-ferrous separator in between. (thin cardboard not recommended)

– Never attach this magnet to tight recessed parts of ferrous metal as you might never be able to remove it, in short it may be stuck permanently!*

(Method of removing large sized neodymium magnets from ferrous metal is to slide it to the edge before prying it off, if this magnet got stuck in a tight recessed area it is very difficult to remove)

– Wear thick gloves when handling neodymium magnet of such size to prevent or reduce injury in events of magnets slamming in to fingers or hand.

– Protective eye wear is also recommended to protect from your eyes from splinters of magnets which might have broken away should high impact collision accident happen.

*However, if you ever get into such a situation, attach to the magnet a flat end, solid thick ferrous rod of the same diameter or greater and pry the magnet off the recessed surface.

If the recessed area metal is thinner and have a weaker pull than the solid rod, chances are the magnet will be separated from surface and attached to the rod instead.

The preparation of Nd-Fe-B permanent magnets by rapid solidification processing is described.

The initial rapid quench is typically carried out by melt spinning;

magnetic hardening can be achieved either by quenching directly from the melt or by annealing an overquenched precursor.

In both instances, optimum permanent magnet properties are associated with the formation of a uniform, finely crystalline (<100 nm diam) microstructure consisting primarily of the Nd2Fe14B phase.

Consolidation of the rapidly solidified material into isotropic magnets can be achieved by conventional cold compaction of the powder with a resin binder or by hot pressing to full density.

Owing to the extremely fine grain size, orientation of the isotropic ribbons by grinding followed by magnetization would be extremely difficult.

Crystallographic anisotropy can be achieved, however, by hot deformation.

Alignment occurs entirely by thermomechanical means with rotation of the easy crystallographic direction normal to the direction of plastic flow.

Energy products to 40 MGOe have been achieved by this technique.

Properties of the various types of magnets prepared from this rapidly solidified material are presented as is microstructural data for the material at key points in the manufacturing process.

neodymium permanent magnets

Permanent Magnets Neodymium ALB Materials America

Neodymium:

As part of the rare earth family of permanent magnets, Neodymium (Nd)-Iron (Fe) Boron (B) material is often referred to as Nd and offers the most advanced permanent magnet material available today.

Nd magnets have an excellent dollar value in terms of price per unit of energy product allowing small shapes and sizes with high magnetic fields.

These magnets can be found in high-performance motors, actuators, speakers, hard disk drives, sensors, and numerous other areas.

ALB Materials Inc. (ALB) offers a complete line of Nd magnets.

Characteristics

Lower costs than samarium cobalt

High energy products (up to 56 MGOe)

Good mechanical characteristics

More temperature dependent than samarium cobalt

Susceptible to surface oxidation and often require a suitable surface treatment

neodymium speaker magnets

Are neodymium magnets only used in small speakers?

Neodymium magnets demagnetize due to high temperatures. For high-powered loudspeakers, it is difficult to avoid overheating. But if we Install some heatsinks, it

Many people say that neodymium magnets are only used on headphones or small speaker, and that is rarely used on large-sized speakers.

They cited several reasons.

Let us check is it really?

The neodymium iron boron magnet is not high temperature resistant, and the H grade magnets (commonly used in most of the product) will start demagnetized beyond 120 degrees Celsius.

More than 300 degrees Celsius, completely demagnetized.

Neodymium magnets demagnetize due to high temperatures.

For high-powered loudspeakers, it is difficult to avoid overheating.

But if we Install some heatsinks, it will increase the weight and volume, and then the transportation costs will be increased too.

The cost is also not as good as ferrites.

Heavyweight and high transportation costs.

As we all know, neodymium magnets are magnetic and small in size.

But why do many people still say that they have a large weight and high transportation costs? That’s because many people think that when the big high-power speaker works, it will over-heated, in order to avoid demagnetize, the speaker needs a fan or other cooling accessory to make the lama cool down.

In this case, the fan will make the heavy-duty speaker heavier.

For a single loudspeaker that has a weight of more than 100kg, if the weight is heavier, it will further increase transportation costs.

High price.

Compared to other kinds of magnets, the price of neodymium magnets is indeed higher.

This will make the product difficult to sell.

Alnico magnets are relatively inexpensive.

So manufactory doesn’t use neodymium magnet on large-size speaker.

The above three reasons are the reasons why everyone thinks that large speakers do not use neodymium magnets in large size speaker.

But are these reasons really true?

The answer is false.

That s not true.

In fact, there are many big brand speakers in the market that already use neodymium magnets.

For example, Faital Pro ‘s 18-inch bass speaker use neodymium magnet;

top manufacturer German BMS , 18-inch 1200W AES power speaker.

Because these are top speakers, so there are not too many consumers know that, but the HiFi big fans know it.

Now let us explain these three reasons for you.

large-size speaker, especially the air flow in the low-noise body, is also very strong and can play a certain role in heat dissipation.

Meanwhile, there are lots of manufacturers through a special design to further reduce the temperature of the speaker.

The only consideration for using neodymium magnets is weight and volume.

After all, large speakers are often moved, and logistics costs are a factor to be considered.

In fact, many brands of speakers don’t need additional equipment for the cooling.

But the speaker can effectively reduce the temperature.

And protect the speaker well, no need to worry about the over-heating.

3.About the cost, in fact, the cost is actually not within the factory’s consideration.

Because of the relative price of large speakers and the savings in logistics costs, the price of Neodymium magnets is only a small problem.

Custom Neodymium Ring&Block Magnets

Neodymium Iron Boron (NdFeB) magnets, of the Rare Earth class, are made from the alloys neodymium, iron and boron and are the most commonly used ...

All shapes and sizes (±0.005)

Magnetism Direction Options

Square and rectangular Sintered Neodymium magnets can be magnetized with two poles ("N" & "S") thru the length, width, thickness and with multiple poles.

Round Sintered Neodymium magnet can be magnetized with two poles ("N" & "S") the thickness, diametrically and with multiple poles.

Ring Sintered Neodymium magnet can be magnetized with two poles ("N" & "S") thru the thickness, diametrically and with multi poles.

Contact us for magnetism direction of irregular shapes.

Caution!

Extreme caution must be taken when working with rare earth magnets.

Magnets larger than a few centimeters are strong enough to cause injuries to body parts pinched between two magnets, or a magnet and a metal surface, even causing broken bones.

Magnets allowed to get too close to each other can strike one another with force to chip and shatter the brittle material, and the flying chips can cause injuries.

Part of the content in this article is reproduced from other media for the purpose of transmitting more information and does not mean that this website agrees with its views or confirms the authenticity of its content. It shall not bear direct responsibility and joint liability for the infringement of such works.

If there is any infringement, bad information, error correction, and other issues in the content of this page, please contact us at info@albmaterials.com

Link to this article: https://www.albmagnets.com/blog/neodymium-n52-permanent-magnets-with-countersunk-holes.html

How to choose and buy a strong neodymium magnet? ALBMagnets is a professional company for strong magnet design and manufacturing,

providing you with reliable N35, N38, N42, N52, N42SH and other grade super neodymium magnets and SmCo rare earth magnets.