401 Ryland St. Ste 200-A,

Reno, NV 89502

United States

E-mail: sales@albmaterials.com

- RX4C2 Neodymium Magnets, 1 1/4 inch od x 3/4 inch id x 1/8 inch thick

- SB443-IN Neodymium Magnets, 1/4 inch length x 1/4 inch width x 3/16 inch thick, with step IN

- D5Z0 Neodymium Magnets, 5/16 inch dia. x 3 inch thick

- D2x3mm Neodymium Magnet, 2 x 3mm Cylinder Magnet

- D100x20mm Neodymium Magnet, 100 x 20mm Disc Magnet

- D1x2mm Neodymium Magnet, 1 x 2mm Cylinder Magnet

- R822 Neodymium Magnets, 1/2 inch od x 1/8 inch id x 1/8 inch thick

- B634 Neodymium Magnets, 3/8 inch x 3/16 inch x 1/4 inch thick

- B50x10x10mm Neodymium Magnet, 50 x 10 x 10mm Block Magnet

- DY0X8 Neodymium Magnets, 2 inch dia. x 1 1/2 inch thick

- D-D12H2-N42 Neodymium Magnet, 12x2mm Disc Magnet

- B40x6x4mm Neodymium Magnet, 40 x 6 x 4mm Block Magnet

- D2H2 Neodymium Magnets, 1/8 inch dia. x 2/10 inch thick

- S8 Neodymium Magnets, 1/2 inch diameter

- RX08X0 Neodymium Magnets, 1 inch od x 1/2 inch id x 1 inch thick

- B3301 Neodymium Magnets, 3/16 inch x 3/16 inch x 1/32 inch thick

Glossary of Magnet Terminology

Glossary of Magnet Terminology

Common parameters of rare earth magnets:

Material: the composition of magnets, like NdFeB(an alloy of neodymium, iron and boron) or SmCo(an alloy of samarium and cobalt)

Shape: the physical shape of a magnet, like Disc, Cylinder, Block, Bar, Cube, Ring, Tube, Sphere, Ball, Arc & Wedge, or custom-made shape as drawing

Dimension: The physical size of a magnet including any plating or coating.

Tolerances: An allowance, given as a permissible range, in the nominal dimensions of a finished magnet. The purpose of a tolerance is to specify the allowed leeway for variations in manufacturing.

Weight: The weight of a single magnet

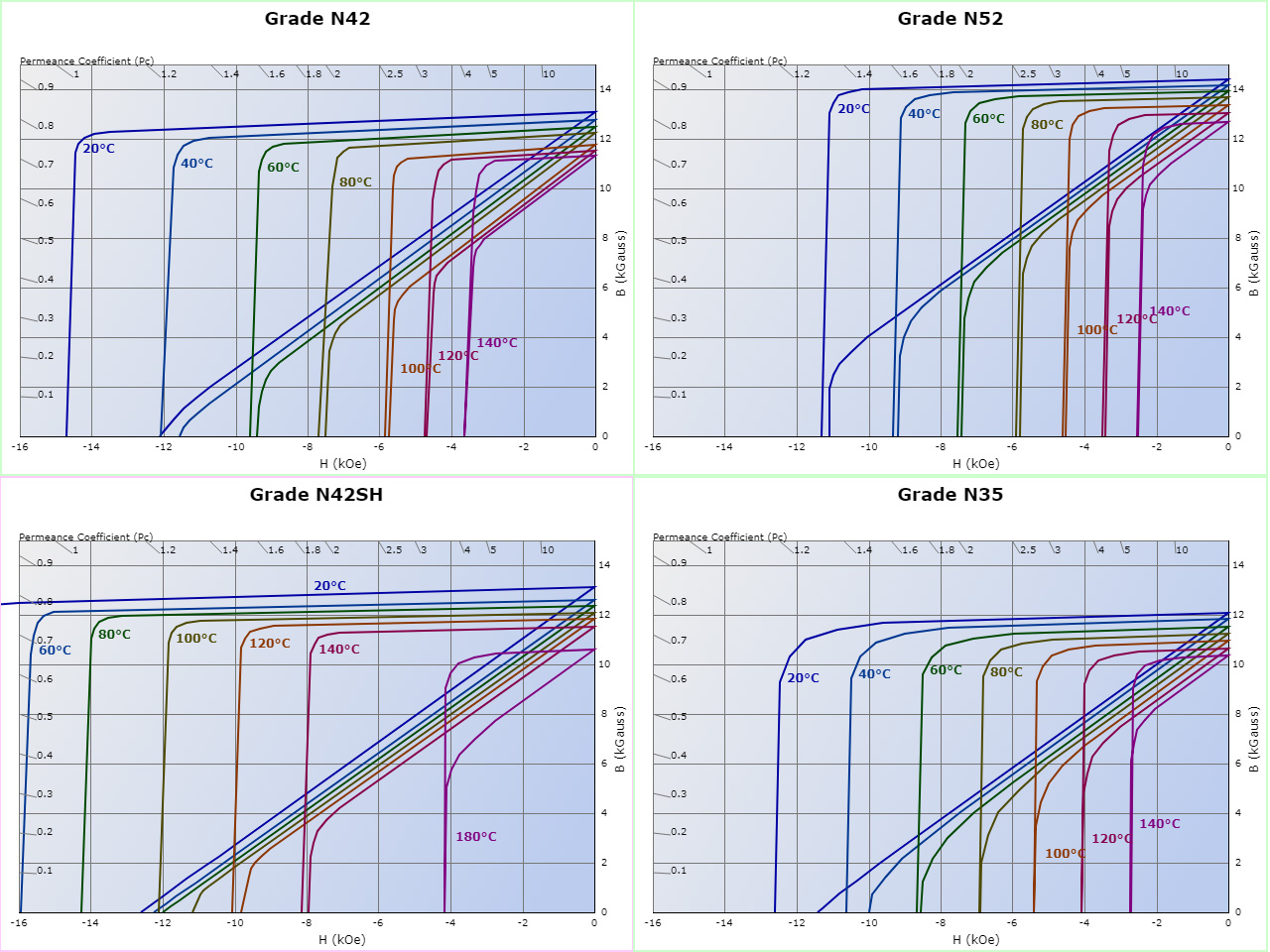

Grade: Neodymium (NdFeB) magnets are graded by the magnetic material from which they are manufactured. Generally speaking, the higher the grade of material, the stronger the magnet. We find that the Pull Force of a magnet relates directly to the "N" number. Neodymium magnets currently range in grade from N35 to N52. The theoretical limit for Neodymium magnets is grade N64, though it isn't currently feasible to manufacture magnets this strong. The grade of most of our stock magnets is N42 because we feel that N42 provides the optimal balance between strength and cost. We also stock a wide range of sizes in grade N52 for customers who need the strongest permanent magnets available.

Coating: Most neodymium magnets are plated or coated in order to protect the magnet material from corrosion. Neodymium magnets are mostly composed of neodymium, iron, and boron. The iron in the magnet will rust if it is not sealed from the environment by some sort of plating or coating. Most of the neodymium magnets that we stock are triple plated in nickel-copper-nickel, but some are plated in gold, silver, or black nickel, while others are coated in epoxy, plastic or rubber.

Pull Force(Lbs): The force required to pull a magnet free from a flat steel plate using force perpendicular to the surface. The limit of the holding power of a magnet. The pull force listed is actual data acquired by testing using our state-of-the-art force test stand.

Surface Field(Gauss): The magnetic field strength at the surface of the magnet as measured by a Gauss meter.

Magnetization direction: the direction from south pole to north pole, please refer: Magnetization direction

Max Operating Temp: or Maximum Operating Temperature (Tmax), also known as maximum service temperature, is the temperature at which the magnet may be exposed to continuously with no significant long-range instability or structural changes.

Unit:

Gauss -The gauss, abbreviated as G or Gs, is the cgs unit of measurement of magnetic flux density (or "magnetic induction") (B). One gauss is defined as one maxwell per square centimeter. The cgs system has been superseded by the International System of Units (SI), which uses the tesla (symbol T) as the unit of magnetic flux density. One gauss equals 1×10−4 tesla (100 μT), so 1 tesla = 10,000 gauss.

Gauss meter - An instrument used to measure the instantaneous value of magnetic induction, B, usually measured in Gauss (C.G.S.). Also called a DC magnetometer.

Gilbert - The unit of magnetomotive force, F, in the C.G.S. system.

Kilogauss - One Kilogauss = 1,000 Gauss = Maxwells per square centimeter.

Maxwell - Unit of magnetic flux in the C.G.S. electromagnetic system. One maxwell is one line of magnetic flux.

Magnetizing Force (H) - The magnetomotive force per unit of magnet length, measured in Oersteds (C.G.S.) or ampere-turns per meter (S.I). Maxwell - The C.G.S. unit for total magnetic flux, measured in flux lines per square centimeter.

MGOe - Mega (million) Gauss Oersteds. Unit of measure typically used in stating the maximum energy product for a given material. See Maximum Energy Product.

Oersted (Oe) - The C.G.S. unit for magnetizing force. The English system equivalent is Ampere Turns per Inch (1 Oersted equals 79.58 A/m). The S.I. unit is Ampere Turns per Meter.

Tesla - The S.I. unit for magnetic induction (flux density). One Tesla equals 10,000 Gauss.

Weber - The S.I. unit for total magnetic flux. The practical unit of magnetic flux. It is the amount of magnetic flux which, when linked at a uniform rate with a single-turn electric circuit during an interval of 1 second, will induce in this circuit an electromotive force of 1 volt.

Glossary of Magnet Terminology

1. Anisotropic Magnet

Anisotropic - An anisotropic material has different properties in different directions. Neodymium magnets are anisotropic. Even before it is magnetized, a neodymium magnet has a preferred direction of magnetic orientation, the magnetic characteristics are optimum in that direction.

Neodymium magnets are made with a preferred magnetization direction which can not be changed. These materials are either manufactured in the influence of strong magnetic fields or pressed a specific way, and can only be magnetized through the preferred axis. Sintered Neodymium (Iron Boron) and Samarium Cobalt magnets are anisotropic.

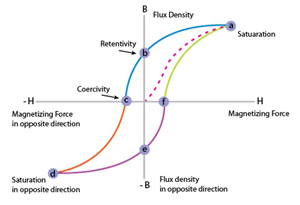

2. B/H Curve, B-H Curve, Hysteresis

The B/H curve is the curve characteristic of the magnetic properties of a material or element or alloy. It tells you how the material responds to an external magnetic field, and is a critical piece of information when designing magnetic circuits. This curve describes the qualities of any magnetic material.

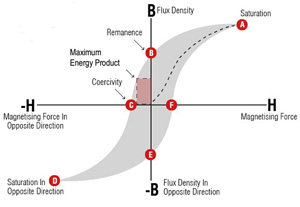

3. BHmax (Maximum Energy Product)

The maximum energy product is a measurement for the maximum amount of magnetic energy stored in a magnet. It concerns the product maximally attainable with a material made out of flux density B and field strength H. In the below picture, it is the area inside the box, under the curve.

The standard unit of measurement is kJ/m³ (Kilojoule per cubic meter) or MGOe (Mega-Gauss-Oersted). When describing the grade of a neodymium magnet, this number is commonly referred to as the "N" number, as in Grade N42 magnets.

You can use either a small magnet with a higher energy product or a large magnet with a smaller energy product for the same use.

The maximum energy product of our super magnets can be viewed in this table.

4. Brmax (Residual Induction)

The residual induction (Brmax, Remanence, Retentivity, Residual Flux Density) is any magnetic induction that remains in a magnetic material after removal of an applied saturating magnetic field, measured in gauss or teslas, denoted as Br or Jr. Residual induction is also known as magnetic remanence.

This is the point at which the hysteresis loop crosses the B axis at zero magnetizing force, and represents the maximum flux output from the given magnet material.

5. Coercive force, Hc

Coercive force or coercivity, this means the value of the external magnetic field that brings to zero the magnetization or magnetic flux density of a magnetic body when that external magnetic field is caused to operate in the opposite direction from the orientation of the magnetization of the magnetic body.

The value of the external magnetic field when the magnetic polarization (or magnetization) and magnetic flux density of the magnetic body come to zero are written as HcJ and HcB to distinguish them, but when evaluating magnetic characteristics, normally the coercive force means HcJ. This means the stability of magnetization in the face of an external magnetic field or the capacity to resist an external magnetic field. Material with high coercive force is hard magnetic material and material with low coercive force is soft magnetic material. This is the most important characteristic for a permanent magnet material.

6. Curie temperature, Tc

The temperature at which the parallel alignment of elementary magnetic moments completely disappears, and the materials are no longer able to hold magnetization. At curie temperature, a magnet loses all of its magnetic properties.

7. Demagnetization Curve

The second quadrant of the hysteresis loop, generally describing the behavior of magnetic characteristics in actual use. Also known as the B-H Curve.

8. Demagnetization Force

Demagnetizing force, typically in the direction opposite to the force used to magnetize it in the first place. Shock, vibration and temperature can also be demagnetizing forces.

9. Electromagnet

A magnet consisting of a solenoid with an iron core, which has a magnetic field only during the time of current flow through the solenoid.

10. Ferromagnetic Material

A material that either is a source of magnetic flux or a conductor of magnetic flux. Most ferromagnetic materials have some component of iron, nickel, or cobalt.

11. Intrinsic Coercive Force (Hci)

An intrinsic ability of a material to resist demagnetization. Its value is measured in Oersted and corresponds to zero intrinsic induction in the material after saturation. Permanent magnets with high intrinsic coercive force are referred to as “Hard” permanent magnets, which usually associated with high temperature stability.

12. Irreversible Losses

Partial demagnetization of the magnet, caused by exposure to high or low temperatures, external fields, shock, vibration, or other factors. These losses are only recoverable by remagnetization. Magnets can be stabilized against irreversible losses by partial demagnetization induced by temperature cycles or by external magnetic fields.

13. Isotropic Material

A material that can be magnetized along any axis or direction (a magnetically unoriented material). The opposite of Anisotropic Magnet.

14. Magnet

A magnet is an object made of certain materials which create a magnetic field. Every magnet has at least one north pole and one south pole.

15. Magnetic Circuit

Consists of all elements, including air gaps and non-magnetic materials that the magnetic flux from a magnet travels on, starting from the north pole of the magnet to the south pole.

16.Magnetic Field (B)

When specified on our site, the surface field or magnetic field refers to the strength in Gauss. For axially magnetized discs and cylinders, it is specified on the surface of the magnet, along the center axis of magnetization. For blocks, it is specified on the surface of the magnet, also along the center axis of magnetization. For rings, you may see two values. By,center specifies the vertical component of the magnetic field in the air at the center of the ring.By,ring specifies the vertical component of the magnetic field on the surface of the magnet, mid-way between the inner and outer diameters.

17. Magnetic Field Strength (H)

Magnetizing or demagnetizing force, is the measure of the vector magnetic quantity that determines the ability of an electric current, or a magnetic body, to induce a magnetic field at a given point; measured in Oersteds.

18.Magnetic Flux

Is a contrived but measurable concept that has evolved in an attempt to describe the "flow" of a magnetic field. When the magnetic induction, B, is uniformly distributed and is normal to the area, A, the flux, Φ = BA.

19. Magnetic Flux Density

Lines of flux per unit area, usually measured in Gauss (C.G.S.). One line of flux per square centimeter is one Maxwell.

20. Magnetic Induction (B)

The magnetic field induced by a field strength, H, at a given point. It is the vector sum, at each point within the substance, of the magnetic field strength and the resultant intrinsic induction. Magnetic induction is the flux per unit area normal to the direction of the magnetic path.

21. Magnetic Line of Force

An imaginary line in a magnetic field, which, at every point, has the direction of the magnetic flux at that point.

22. Magnetic Pole

An area where the lines of flux are concentrated.

23. Magnetomotive Force (F or mmf)

The magnetic potential difference between any two points. Analogous to voltage in electrical circuits. That which tends to produce a magnetic field. Commonly produced by a current flowing through a coil of wire. Measured in Gilberts (C.G.S.) or Ampere Turns (S.I.).

24. Magnetization Curve

The first quadrant portion of the hysteresis loop (B/H) Curve for a magnetic material.

25. Magnetizing Force (H)

The magnetomotive force per unit of magnet length, measured in Oersteds (C.G.S.) or ampere-turns per meter (S.I). Maxwell - The C.G.S. unit for total magnetic flux, measured in flux lines per square centimeter.

26. North Pole

The north pole of a magnet is the one attracted to the magnetic north pole of the earth. This north-seeking pole is identified by the letter N. By accepted convention, the lines of flux travel from the north pole to the south pole.

27. Orientation

Used to describe the direction of magnetization of a material. Orientation Direction - The direction in which an anisotropic magnet should be magnetized in order to achieve optimum magnetic properties.

28. Paramagnetic Materials

Materials that are not attracted to magnetic fields (wood, plastic, aluminum, etc.). A material having a permeability slightly greater than 1.

29. Permanent Magnet

A magnet that retains its magnetism after it is removed from a magnetic field. A permanent magnet is "always on". Neodymium magnets are permanent magnets.

30. Permeance (P)

A measure of relative ease with which flux passes through a given material or space. It is calculated by dividing magnetic flux by magnetomotive force. Permeance is the reciprocal of reluctance.

31. Permeance Coefficient (Pc)

Also called the load-line, B/H or "operating slope" of a magnet, this is the line on the Demagnetization Curvewhere a given magnet operates. The value depends on both the shape of the magnet, and it's surrounding environment (some would say, how it's used in a circuit). In practical terms, it's a number that define how hard it is for the field lines to go from the north pole to the south pole of a magnet. A tall cylindrical magnet will have a high Pc, while a short, thin disc will have a low Pc.

32. Permeability (μ)

The ratio of the magnetic induction of a material to the magnetizing force producing it (B/H). It is a measure of how much a material becomes magnetized in the presence of a magnetic field. The magnetic permeability of a vacuum (µo) is 4π×10-7 N/A2.

33. Pole

An area where the lines of magnetic flux are concentrated.

34. Polarity

The characteristic of a particular pole at a particular location of a permanent magnet. Differentiates the North from the South Pole.

35. Rare Earth

Commonly used to describe high energy magnet material such as NdFeB (Neodymium-Iron-Boron) and SmCo (Samarium-Cobalt).

36. Relative Permeability

The ratio of permeability of a material to that of a vacuum. In the C.G.S. system, the permeability is equal to 1 in a vacuum by definition. The permeability of air is also for all practical purposes equal to 1 in the C.G.S. system.

37. Reluctance (R

A measure of the relative resistance of a material to the passage of flux. It is calculated by dividing magnetomotive force by magnetic flux. Reluctance is the reciprocal of permeance.

38. Remanence, (Bd)

The magnetic induction that remains in a magnetic circuit after the removal of an applied magnetizing force.

39. Return Path

Conduction elements in a magnetic circuit which provide a low reluctance path for the magnetic flux.

40. Reversible Temperature Coefficient

A measure of the reversible changes in flux caused by temperature variations.

41.Saturation

The state where an increase in magnetizing force produces no further increase in magnetic induction in a magnetic material.

42. Sintering

The bonding of powder compacts by the application of heat to enable one or more of several mechanisms of atom movement into the particle contact interfaces to occur; the mechanisms are: viscous flow, liquid phase solution-precipitation, surface diffusion, bulk diffusion, and evaporation-condensation. Densification is a usual result of sintering.

43. South Pole

The south pole of a magnet is the one attracted to the south pole of the earth. This south-seeking pole is identified by the letter S. By accepted convention, the lines of flux travel from the north pole to the south pole.

44. Stabilization

The process of exposing a magnet or a magnetic assembly to elevated temperatures or external magnetic fields to demagnetize it to a predetermined level. Once done the magnet will suffer no future degradation when exposed to that level of demagnetizing influence.

45. Stability

An ability to resist to demagnetizing influences expected to be encountered in operation. These demagnetizing influences can be caused by high or low temperatures or by external magnetic fields.

46. Temperature Coefficient

A factor that is used to calculate the decrease in magnetic flux corresponding to an increase in operating temperature. The loss in magnetic flux is recovered when the operating temperature is decreased.

Part of the content in this article is reproduced from other media for the purpose of transmitting more information and does not mean that this website agrees with its views or confirms the authenticity of its content. It shall not bear direct responsibility and joint liability for the infringement of such works.

If there is any infringement, bad information, error correction, and other issues in the content of this page, please contact us at info@albmaterials.com

Link to this article: https://www.albmagnets.com/blog/glossary-of-magnet-terminology.html

How to choose and buy a strong neodymium magnet? ALBMagnets is a professional company for strong magnet design and manufacturing,

providing you with reliable N35, N38, N42, N52, N42SH and other grade super neodymium magnets and SmCo rare earth magnets.