401 Ryland St. Ste 200-A,

Reno, NV 89502

United States

E-mail: sales@albmaterials.com

- B5x4x1.7mm Neodymium Magnet, 5 x 4 x 1.7mm Block Magnet

- D8x30mm Neodymium Magnet, 8 x 30mm Cylinder Magnet

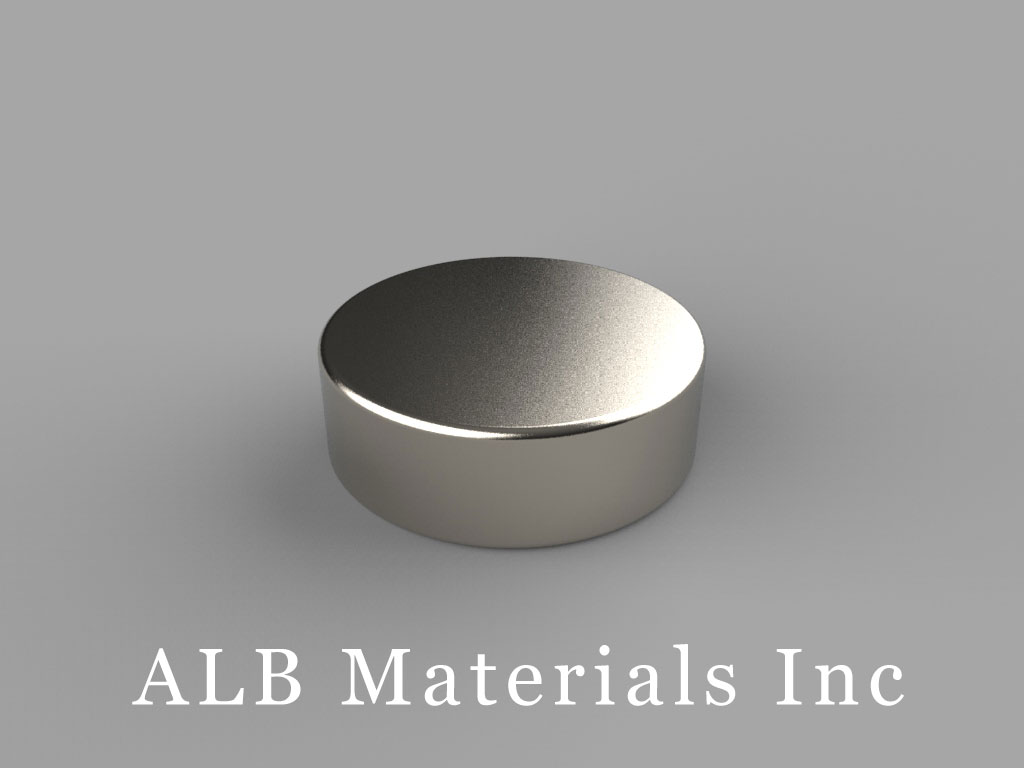

- D-D10H5-N45 Neodymium Magnet, 10x5mm Disc Magnet

- BY0Y01 Neodymium Magnets, 2 inch x 2 inch x 1/16 inch thick

- S3 Neodymium Magnets, 3/16 inch diameter

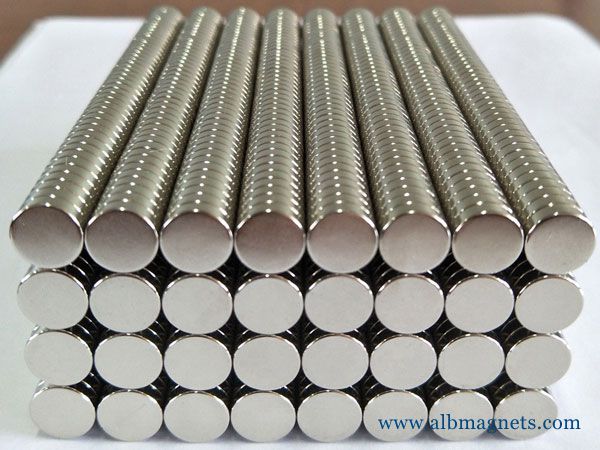

- D-D12H1.5-N42 Neodymium Magnet, 12x1.5mm Disc Magnet

- D-D50H3-N35 Neodymium Magnet, 50x3mm Disc Magnet

- B20x4x3mm Neodymium Magnet, 20 x 4 x 3mm Block Magnet

- B100x20x5mm Neodymium Magnet, 100 x 20 x 5mm Block Magnet

- DX2Z0 Neodymium Magnets, 1 1/8 inch dia. x 3 inch thick

- D-D12H5-N42 Neodymium Magnet, 12x5mm Disc Magnet

- B100x10x5mm Neodymium Magnet, 100 x 10 x 5mm Block Magnet

- C-D12.7H31.75-N40 Neodymium Magnet, 12.7x31.75mm Cylinder Magnet

- C-D6.85H15-N50M Neodymium Magnet, 6.85x15mm Cylinder Magnet

- D4x3mm Neodymium Magnet, 4 x 3mm Disc Magnet

- SX0 Neodymium Magnets, 1 inch diameter

5 Examples Of Magnetic Materials

5 examples of magnetic materials

Classes of Magnetic Materials

The origin of magnetism lies in the orbital and spin motions of electrons and how the electrons interact with one another.

The best way to introduce the different types of magnetism is to describe how materials respond to magnetic fields.

This may be surprising to some, but all matter is magnetic.

It's just that some materials are much more magnetic than others.

The main distinction is that in some materials there is no collective interaction of atomic magnetic moments, whereas in other materials there is a very strong interaction between atomic moments.

The magnetic behavior of materials can be classified into the following five major groups:

Magnetic Properties of some common minerals

Materials in the first two groups are those that exhibit no collective magnetic interactions and are not magnetically ordered.

Materials in the last three groups exhibit long-range magnetic order below a certain critical temperature.

Ferromagnetic and ferrimagnetic materials are usually what we consider as being magnetic (ie., behaving like iron).

The remaining three are so weakly magnetic that they are usually thought of as "nonmagnetic".

1. Diamagnetism

Diamagnetism is a fundamental property of all matter, although it is usually very weak.

It is due to the non-cooperative behavior of orbiting electrons when exposed to an applied magnetic field.

Diamagnetic substances are composed of atoms that have no net magnetic moments (ie., all the orbital shells are filled and there are no unpaired electrons).

However, when exposed to a field, a negative magnetization is produced and thus the susceptibility is negative.

If we plot M vs H, we see:

Note that when the field is zero the magnetization is zero.

The other characteristic behavior of diamagnetic materials is that the susceptibility is temperature independent.

Some well known diamagnetic substances, in units of 10-8 m3/kg, include: quartz (SiO2) -0.62

2. Paramagnetism

This class of materials, some of the atoms or ions in the material have a net magnetic moment due to unpaired electrons in partially filled orbitals.

One of the most important atoms with unpaired electrons is iron.

However, the individual magnetic moments do not interact magnetically, and like diamagnetism, the magnetization is zero when the field is removed.

In the presence of a field, there is now a partial alignment of the atomic magnetic moments in the direction of the field, resulting in a net positive magnetization and positive susceptibility.

In addition, the efficiency of the field in aligning the moments is opposed by the randomizing effects of temperature.

This results in a temperature-dependent susceptibility, known as the Curie Law.

At normal temperatures and in moderate fields, the paramagnetic susceptibility is small (but larger than the diamagnetic contribution).

Unless the temperature is very low (<<100 K) or the field is very high paramagnetic susceptibility is independent of the applied field.

Under these conditions, paramagnetic susceptibility is proportional to the total iron content.

Many iron-bearing minerals are paramagnetic at room temperature.

Some examples, in units of 10-8 m3/kg, include:

Montmorillonite (clay) 13

Siderite(carbonate) 100

Pyrite (sulfide) 30

The paramagnetism of the matrix minerals in natural samples can be significant if the concentration of magnetite is very small.

In this case, a paramagnetic correction may be needed.

3. Ferromagnetism

When you think of magnetic materials, you probably think of iron, nickel or magnetite.

Unlike paramagnetic materials, the atomic moments in these materials exhibit very strong interactions.

These interactions are produced by electronic exchange forces and result in a parallel or antiparallel alignment of atomic moments.

Exchange forces are very large, equivalent to a field on the order of 1000 Tesla, or approximately 100 million times the strength of the earth's field.

The exchange force is a quantum mechanical phenomenon due to the relative orientation of the spins of two-electron.

Ferromagnetic materials exhibit parallel alignment of moments resulting in large net magnetization even in the absence of a magnetic field.

The elements Fe, Ni, and Co and many of their alloys are typical ferromagnetic materials.

Two distinct characteristics of ferromagnetic materials are their

(1) spontaneous magnetization and the existence of

(2) magnetic ordering temperature

Spontaneous Magnetization

The spontaneous magnetization is the net magnetization that exists inside a uniformly magnetized microscopic volume in the absence of a field.

The magnitude of this magnetization, at 0 K, is dependent on the spin magnetic moments of electrons.

A related term is the saturation magnetization which we can measure in the laboratory.

The saturation magnetization is the maximum induced magnetic moment that can be obtained in a magnetic field (Heat);

beyond this field, no further increase in magnetization occurs.

The difference between spontaneous magnetization and the saturation magnetization has to do with magnetic domains (more about domains later).

Saturation magnetization is an intrinsic property, independent of particle size but dependent on temperature.

There is a big difference between paramagnetic and ferromagnetic susceptibility.

As compared to paramagnetic materials, the magnetization in ferromagnetic materials is saturated in moderate magnetic fields and at high (room-temperature) temperatures:

Heat Tesla

1000-10000

Curie Temperature

Even though electronic exchange forces in ferromagnets are very large, thermal energy eventually overcomes the exchange and produces a randomizing effect.

This occurs at a particular temperature called the Curie temperature (TC).

Below the Curie temperature, the ferromagnet is ordered and above it, disordered.

The saturation magnetization goes to zero at the Curie temperature.

A typical plot of magnetization vs temperature for magnetite is shown below.

The Curie temperature is also an intrinsic property and is a diagnostic parameter that can be used for mineral identification.

However, it is not foolproof because different magnetic minerals, in principle, can have the same Curie temperature.

Hysteresis

In addition to the Curie temperature and saturation magnetization, ferromagnets can retain a memory of an applied field once it is removed.

This behavior is called hysteresis and a plot of the variation of magnetization with a magnetic field is called a hysteresis loop.

Another hysteresis property is the coercivity of remanence (Hr).

This is the reverse field which, when applied and then removed, reduces the saturation remanence to zero.

It is always larger than the coercive force.

The initial susceptibility (χ0) is the magnetization observed in low fields, on the order of the earth's field (50-100 μT).

The various hysteresis parameters are not solely intrinsic properties but are dependent on grain size, domain state, stresses, and temperature.

Because hysteresis parameters are dependent on grain size, they are useful for the magnetic grain sizing of natural samples.

4. Ferrimagnetism

In ionic compounds, such as oxides, more complex forms of magnetic ordering can occur as a result of the crystal structure.

One type of magnetic ordering is called ferrimagnetism.

A simple representation of the magnetic spins in a ferrimagnetic oxide is shown here.

The magnetic structure is composed of two magnetic sublattices (called A and B) separated by oxygens.

The exchange interactions are mediated by the oxygen anions.

When this happens, the interactions are called indirect or superexchange interactions.

The strongest superexchange interactions result in an antiparallel alignment of spins between the A and B sublattice.

In ferrimagnets, the magnetic moments of the A and B sublattices are not equal and result in a net magnetic moment.

Ferrimagnetism is therefore similar to ferromagnetism.

It exhibits all the hallmarks of ferromagnetic behavior- spontaneous magnetization, Curie temperatures, hysteresis, and remanence.

However, ferro- and ferrimagnets have very different magnetic ordering.

Magnetite is a well known ferrimagnetic material.

Indeed, magnetite was considered a ferromagnet until Néel in the 1940's, provided the theoretical framework for understanding ferrimagnetism.

Crystal Structure of Magnetite

Magnetite, Fe3O4 crystallizes with the spinel structure.

The large oxygen ions are close packed in a cubic arrangement and the smaller Fe ions fill in the gaps.

The gaps come in two flavors:

tetrahedral site: Fe ion is surrounded by four oxygens

octahedral site: Fe ion is surrounded by six oxygens

The tetrahedral and octahedral sites form the two magnetic sublattices, A and B respectively.

The spins on the A sublattice are antiparallel to those on the B sublattice.

The two crystal sites are very different and result in complex forms of exchange interactions of the iron ions between and within the two types of sites.

The structural formula for magnetite is

[Fe3+]A [Fe3+,Fe2+]B O4

This particular arrangement of cations on the A and B sublattice is called an inverse spinel structure.

With negative AB exchange interactions, the net magnetic moment of magnetite is due to the B-site Fe2+.

5. Antiferromagnetism

If the A and B sublattice moments are exactly equal but opposite, the net moment is zero.

This type of magnetic ordering is called antiferromagnetism.

The clue to antiferromagnetism is the behavior of susceptibility above a critical temperature, called the Néel temperature (TN).

Above TN, the susceptibility obeys the Curie-Weiss law for paramagnets but with a negative intercept indicating negative exchange interactions.

Crystal Structure of Hematite

Hematite crystallizes in the corundum structure with oxygen ions in a hexagonal close-packed framework.

The magnetic moments of the Fe3+ ions are ferromagnetically coupled within specific c-planes, but antiferromagnetically coupled between the planes.

Above -10°C, the spin moments lie in the c-plan but are slightly canted.

This produces a weak spontaneous magnetization within the c-plan (σs = 0.4 Am2/kg).

Below -10°C, the direction of the antiferromagnetism changes and becomes parallel to the c-axis;

there is no spin canting and hematite becomes a perfect antiferromagnet.

This spin-flop transition is called the Morin transition.

List of Metals That Are Attracted to Magnets

then the force attracting ferromagnetic materials; so you'll never feel the attraction from holding a magnet to a piece of magnesium, for example.

Three types of metals interact with magnetic fields: ferromagnetic, paramagnetic and diamagnetic metals.

Ferromagnetic metals are strongly attracted to magnets;

the rest are not.

Magnets also attract paramagnetic metals, but very weakly.

Diamagnetic metals repel the magnet, though the force is typically very weak.

Ferromagnetic Metals

Ferromagnetic metals are strongly attracted by a magnetic force.

The common ferromagnetic metals include iron, nickel, cobalt, gadolinium, dysprosium, and alloys such as steel that also contain specific ferromagnetic metals such as iron or nickel.

Ferromagnetic metals are commonly used to make permanent magnets.

Non-Attracting Metals

A magnet will weakly attract paramagnetic metals such as magnesium, molybdenum, and tantalum are weakly attracted to a magnetic force.

The attractive force is about a million times weaker than the force attracting ferromagnetic materials;

so you'll never feel the attraction from holding a magnet to a piece of magnesium, for example.

Only very sensitive scientific equipment can measure the weak force.

Diamagnetic metals don't attract magnets - they repel them, though weakly.

Examples include copper, carbon, gold, silver, lead and bismuth.

The repelling force is weak for most of these metals, though certain types of pure graphite can "float" a strong magnet.

Magnetic and Non Magnetic Materials and their Properties

These natural magnets have the magnetic property of attracting materials like iron.

Activity - 1

Rub a magnet in the sand or soil.

Pull out the magnet.

Are there some particles of sand or soil sticking to the magnet? Now, gently shake the magnet to remove the particles of sand or soil.

Are some particles still sticking to it? These might be small pieces of iron (iron filings) picked up from the soil.

Through such an activity, we can find out whether the soil or sand from a given place contains particles that have iron.

Try this activity near your home, school or the places you visit on your holidays. Make a table of what you find.

POLES OF MAGNET

We observed that iron filings (if they are present) stick to a magnet rubbed in the soil.

Did you observe anything special about the way they stick to the magnet?

Activity - 2

Spread some iron filings on a sheet of paper.

Now, place a bar magnet on this sheet.

What do you observe? Do the iron filings stick all over the magnet? Do you observe that more iron filings get attracted to some parts of the magnet than others? Remove the iron filings

sticking to the magnet and repeat the activity.

Do you observe any change in the pattern with which the iron filings get attracted by different parts of the magnet? You can do this activity using pins or iron nails in place of iron filings and also with magnets of different shapes.

Draw a diagram to show the way iron filings stick to the magnet. We find that most of the iron filings are attracted to the two ends of a bar magnet.

These ends are the poles of the magnet.

Try and bring a few magnets of different shapes to the classroom.

Check for the location of the poles on these magnets using iron filings.

Can you now mark the location of poles in the kind of magnets?

Finding Directions

Magnets were known to people from ancient times.

Many properties of magnets were also known to them.

You might have read many interesting stories about the uses of magnets.

One such story is about an emperor in China named Hoang Ti.

It is said that he had a chariot with a statue of a lady that could rotate in any direction.

It had an extended arm as if it was showing the way.

The statue had an interesting property.

It would rest in such a position that its extended arm always pointed towards the South.

By looking at the extended arm of the statue, the Emperor was able to locate directions when he went to new places on his.

Let us make such a direction finder for ourselves.

Activity - 3

Take a bar magnet.

Put a mark on one of its ends for identification.

Now, tie a thread at the middle of the magnet that you may suspend it from a wooden stand.

Make sure that the magnet can rotate freely.

Let it come to rest.

Mark two points on the ground to show the position of the ends of the magnet when it comes to rest.

Draw a line joining the two points.

This line shows the direction in which the magnet was pointing in its position of rest.

Now, rotate the magnet by gently pushing one end in any direction and let it come to rest.

Again, mark the position of the two ends in its position of rest.

Does the magnet now point in a different direction? Rotate the magnet in other directions and note the final direction in which it comes to rest.

Do you find that the magnet always comes to rest in the same direction? Now can you guess the mystery behind the statue in the Emperor's chariot?

Repeat this activity with an iron bar and a plastic or a wooden scale instead of a magnet.

Do not use light objects for this activity and avoid doing it where there are currents of air.

Do the other materials also always come to rest in the same direction?

We find that a freely suspended bar magnet always comes to rest in a particular direction, which is the North-South direction.

Use the direction of the rising sun in the morning to find out the rough direction towards the east, where you are doing this experiment.

If you stand facing east, to your left will be North.

Using the Sun for finding directions may not be very exact, but, it will help to make out the direction North from the South, on your line.

Using this you can figure out which end of the magnet is pointing to the North and which points to the South.

The end of the magnet that points towards the North is called it's North seeking the end of the North pole of the magnet.

The other end that points towards the South are called the South seeking the end of the South pole of the magnet.

All magnets have two poles whatever their shape may be.

Usually, north (N) and south (S) poles are marked on the magnets.

This property of the magnet is very useful for us.

For centuries, travelers have been making use of this property of magnets to find directions.

It is said that in olden days, travelers used to find directions by suspending natural magnets with a thread, which they always carried with them.

Later on, a device was developed based on this property of magnets.

It is known as the compass.

A compass is usually a small box with a glass cover on it.

A magnetized needle is pivoted inside the box, which can rotate freely.

The compass also has a dial with directions marked on it.

The compass is kept at the place where we wish to know the directions.

Its needle indicates the north-south direction when it comes to rest.

The compass is then rotated until the north and south marked on the dial are at the two ends of the needle.

To identify the north pole of the magnetic needle, it is usually painted in a different color.

Magnetic and non-magnetic materials

We have now looked at a number of ways in which matter can be grouped, such as into metals, semi-metals, and non-metals;

electrical conductors and insulators, and thermal conductors and insulators.

One way in which we can further group metals is to divide them into those that are magnetic and those that are non-magnetic.

Magnetism is a force that certain kinds of objects, which are called 'magnetic' objects, can exert on each other without physically touching.

A magnetic object is surrounded by a magnetic 'field' that gets weaker as one moves further away from the object.

A metal is said to be ferromagnetic if it can be magnetized (i.e.made into a magnet).

If you hold a magnet very close to a metal object, it may happen that its own electrical field will be induced and the object becomes magnetic.

Some metals keep their magnetism for longer than others.

Look at iron and steel for example.

Iron loses its magnetism quite quickly if it is taken away from the magnet.

Steel, on the other hand, will stay magnetic for a longer time.

Steel is often used to make permanent magnets that can be used for a variety of purposes.

Magnets are used to sort the metals in a scrap yard, in compasses to find direction, in the magnetic strips of videotapes and ATM cards where information must be stored, in computers and TV's, as well as in generators and electric motors.

You can test whether an object is magnetic or not by holding another magnet close to it.

If the object is attracted to the magnet, then it too is magnetic.

Fun With Magnets

Activity I

Collect different materials from your surroundings like Iron nail, brass screw, aluminum foil, plastic comb, coin, sewing needle, copper wire, aluminum foil, glass marble, eraser, stainless steel spoon, plastic ruler, pencil, etc.

Now bring a magnet close to the objects.

Observation: We will observe that some materials like Iron nail, Sewing needle, and coin are attracted to a magnet while the other substances like a brass screw, Aluminium foil, plastic comb, etc do not get attracted to a magnet.

1. Magnetic Materials

Those materials which are attracted b a magnet are magnetic materials.

Iron, Nickel, and Cobalt are the magnetic substances as objects made up of these materials are attracted by a magnet.

Also, magnetic materials can be magnetized or we can say that magnetic materials can be converted into magnets.

2. Non-Magnetic Materials

Those materials which are not attracted by a magnet are called non- magnetic materials.

All the substances other than iron, nickel, and Cobalt are non-magnetic substances for example plastic, rubber, water, etc are nonmagnetic materials.

Non-magnetic substances cannot be magnetized.

Application of Magnetic and Non-Magnetic Materials

We can use magnetic and non-magnetic properties of a substance in daily life for ease of working.

some of them are –

If a large number of pins are fallen from the pin box on the ground, they can be easily collected by using a magnet as pins are made up of iron which is a magnetic material.

If a carpenter mixes iron nails with wood shavings they can be separated easily by using the method of magnetic separation.

A magnet is brought close to the mixture.

Iron nails get attracted to the magnet and stick to it whereas wooden shavings which are made up of non-magnetic material will not be attracted by the magnet.

Activity II

Rohan shows magic to his friends and gains a lot of applause for it.

He keeps a steel car on a wooden table.

Without moving the car by directly pushing it, he is able to move the car.

His friends are amazed and wonder how is it possible.

What is the secret behind his magic? Rohan actually keeps a magnet under the table.

By moving the magnet under the table, he is able to move the car kept on the table without moving it.

This activity shows that force of a magnet can pass through a non-magnetic substance like the wood in this case.

What will be the observation if the table top is made up of iron instead of wood? In this case, the car will not move because the force of a magnet cannot pass through magnetic materials like Iron and Steel objects.

Some Interesting Facts About Magnet

The first known magnets are hard block stones called lodestone.

It is believed to be discovered by Shepherd Magnes who accidentally discovered it while feeding his sheep.

Lodestone which is a natural magnet contains an iron mineral called magnetite.

Magnets are made in different shapes for example bar magnet, horseshoe magnet, disc magnet etc

Learn more about the Properties and Applications of Magnet .

Questions For You

Q1. Seema finds that a sharpener though made up of plastic attracts a magnet.

How is it possible.

Justify her observation.

Ans: The blade attached to the sharpener is made up of magnetic substance (steel) which attracts the magnet.

Q2. Rahul and his friends were decorating the class bulletin board.

They dropped the box of stainless steel pins by mistake.

They tried to collect the pins using a magnet but could not succeed.

What could be the reason for this?

Ans: Stainless steel is not attracted by a magnet.

Magnetic Raw Materials

The five types are alnico, ferrite, flexible rubber, and the rare earth magnets samarium cobalt and neodymium.

To understand magnetism, it is essential to identify what types of materials are used to create magnets and how the materials used affect the ultimate performance of a magnet.

Neodymium / Samarium Cobalt / Alnico / Ferrite

There are a number of elements that are attracted by magnets, commonly referred to as ‘magnetic’.

These are the same materials that can be magnetized to create permanent magnets, Here you can see a list of magnetic elements and minerals:

Magnetic materials are categorized as magnetically hard, or magnetically soft materials.

Magnetically soft materials are easily magnetized but the induced magnetism is usually temporary.

For example, if you rub a permanent magnet along a nail or a screwdriver, the nail or screwdriver will become temporarily magnetized and will emit their own weak magnetic field.

This is because a large number of their iron atoms are temporarily aligned in the same direction by the external magnetic field.

Like magnetically soft materials, magnetically hard materials can be magnetized by a strong external magnetic field, such as those generated by an electromagnet.

The difference being that magnetically hard materials will remain magnetized indefinitely unless they are demagnetized by an opposing magnetic field, raised above their curie temperature or allowed to corrode.

Magnetically hard materials are used to create permanent magnets made from alloys generally consisting of varying amounts of iron, aluminum, nickel, cobalt and rare earth elements samarium, dysprosium, and neodymium.

The strongest permanent magnets are known as neodymium magnets and are made from an alloy of neodymium, iron, and boron.

Permanent magnets are difficult to magnetize as unlike magnetically soft materials their atomic magnetic domains aren’t easily aligned but once they are aligned, they remain so indefinitely.

Classification of magnetic materials

Because all materials have a different atomic structure different materials react differently when placed in a magnetic field.

In its simplest form, the magnetic behavior of a material is determined by its number of unpaired electrons in each atom.

In the atoms of most elements electrons exist in pairs with each electron spinning in a different direction causing them to cancel out each other’s magnetic field, therefore no net magnetic field exists.

However, some materials have unpaired electrons which will generate a net magnetic field and therefore have a greater reaction to an external magnetic field.

Most materials are classified either as ferromagnetic, diamagnetic or paramagnetic.

Magnetic Raw Materials

All the permanent magnets in the world are currently made from five types of material each with very different characteristics.

The five types are alnico, ferrite, flexible rubber, and the rare earth magnets samarium cobalt and neodymium.

What is Ferrite?

Ferrite is a term used to refer to pure iron, the most easily recognizable ferromagnetic material.

It is also a term used to describe ferrite magnetic material which is a compound consisting of strontium carbonate or barium and iron oxide (Fe2O3).

Ferrite magnets have low production costs but are also much weaker than rare earth samarium cobalt and neodymium magnets.

Because of their low production costs, they are one of the most widely used magnetic materials when high magnetic performance is not the most important factor.

Ferrite Magnets Manufacturing

The method for producing ferrite magnets is not as costly or sophisticated as that for manufacturing rare earth magnets and because they are very hard and brittle they are generally manufactured in basic shapes such as squares, cylinders, and rings. The production of ferrite magnets begins with calcining a finely powdered mixture of iron oxide and strontium carbonate to produce a metallic-oxide material.

Once cooled, the already fine powder is then milled a number of times reducing the calcined material to fine particles smaller than 2 micrometers or 2 microns, so that each particle consists of one single magnetic domain.

The powder is then pressed and compacted into a die.

If pressing takes place within an externally applied magnetic field the magnet's particles will be aligned and the magnet produced will be anisotropic.

If the powder is pressed without an externally applied magnetic field the magnet will be isotropic and have weaker magnetic properties.

Once pressed, the compacted particles are then sintered at very high temperatures to make the particles fuse together before finally being magnetized.

Ferrite magnets Magnetic Properties

Ferrite magnets are inexpensive to produce which is relative to their overall magnetic strength.

Despite being significantly weaker than rare earth materials they are still widely used in many commercial applications.

The main strength of ferrite magnets is their resistance to demagnetization and corrosion.

What is Neodymium?

Neodymium (Nd) is a rare earth element with atomic number 60 that was discovered in 1885 by Austrian chemist Carl Auer von Welsbach.

Although part of the rare earth family neodymium is relatively abundant and is no rarer than copper.

Neodymium is mixed with iron and boron as well as traces of other elements such as dysprosium and praseodymium to produce a ferromagnetic alloy known as Nd2Fe14b, the strongest magnetic material in the world.

Developed in 1982 by General Motors and Sumitomo Special Metals, neodymium magnets have replaced other types of magnetic materials in many modern commercial and industrial appliances.

Neodymium Magnets Manufacturing

Before neodymium can be made into neodymium magnets the mined rare earth mineral ore must be refined;

a procedure involving dozens of chemical processes.

Once refined, neodymium is mixed with iron, boron and other required elements to make the desired grade by heating them in a vacuum induction furnace until melted.

Generally, the molten alloy is then cooled to form ingots before being ground into tiny grains in a jet mill.

The super-fine powder is then pressed in a mold while simultaneously being exposed to a large magnetic field produced by an electromagnet.

As the powdered material is pressed the magnetic field aligns the individual magnetic domains of the ferromagnetic material in the direction of the magnetic field.

As the material is pressed the direction is set and the anisotropic material is given its preferred direction of magnetism.

This preferred direction of magnetism contributes to the finished magnet's strength and high coercivity.

If there is no external magnetic field applied during this stage of the process the material’s individual magnetic domains will not all be uniformly aligned (isotropic) and as result, the material can be magnetized in any direction.

However, the finished magnet will have a fraction of an anisotropic magnets strength and will have a lower coercivity.

Neodymium magnets Magnetic Properties

Neodymium magnets are the strongest magnets available and therefore have a high power to volume and weight ratio.

Because they are so strong it also means they have a relatively low cost per unit of strength (Maximum Energy Product, MGOe).

They have an incredibly high resistance to being demagnetized but generally have low maximum operating temperatures compared to other materials and are susceptible to corrosion if their coating is damaged.

Other grades of neodymium magnet, including special high maximum operating temperature grades are available.

What is Alnico (Al-Ni-Co)?

The term alnico is an acronym of aluminum, nickel, and cobalt;

the three primary elements which are used to create alnico magnetic material.

Despite being the first permanent magnets to be developed in the 1920s, rare earth magnets aside, alnico magnets are the strongest permanent magnets available.

The introduction of alnico magnets meant that expensive electromagnets could be replaced with permanent magnets in devices such as motors, generators, and loudspeakers.

Alnico (Al-Ni-Co) Magnets Manufacturing

Alnico magnets have been manufactured for nearly 100 years and during this time the process has not drastically changed.

The primary elements used to create alnico magnets are aluminum, nickel, and cobalt, however, like other types of permanent magnets, traces of other elements are added to produce specific characteristics.

Alnico magnets are manufactured using one of two methods:

Casting

Quantities of the individual elements used to manufacture alnico magnets are put into an induction furnace and melted at over 1750? The molten material is then poured into a shell mold or larger green sand molds.

As the molten metal cools, the shell molds start to burn and by the time the magnets are cold, the shell is almost disintegrated.

Patterns are a similar size to the required magnet size but with an additional allowance for shrinkage and machining to size.

The magnet cavities inside are linked by runners which allow the molten metal to reach each magnet cavity and the runners are then scrapped and re-melted once the magnets are cast.

The newly cast magnets are then removed from the molds before being fettled on grinding wheels to remove the runner gates.

The magnets are then heated to incredibly high temperatures and then placed into magnetizers so that they can start to cool down whilst in the presence of a very strong magnetic field.

The magnets are then placed in large tempering ovens for a few days to temper and stabilize the magnets.

The heat treatment stage of the process in conjunction with the alloy mixture gives the magnetic material its temperature handling characteristics and its final magnetic properties.

Finally, the magnets are inserted into a coil or solenoid magnetizers and in one-fifth of a second, the electrical pulse generates the necessary field needed to fully magnetize the magnets.

Sintering

Before sintered alnico magnets can be produced the raw elements must first be finely ground by milling into tiny particles.

The powdered magnetic material is then pressed under tonnes of pressure in a die, which closely resembles the final desired shape.

Once the powder has been pressed, the material is sintered in a furnace in a hydrogen atmosphere at over 1200?.

This process fuses all the pressed particles together to form one magnet.

The red hot material is then cooled in the presence of an external magnetic field to manufacture an anisotropic magnet or without an external magnetic field to produce an isotropic magnet.

Generally, sintered alnico magnets do not require further shaping or machining as they die they are pressed in is made to be very close to the desired shape of the magnet.

Finally, the raw magnetic material is magnetized by placing it inside a coil or solenoid magnetizer to magnetize the magnets.

Alnico Magnets Magnetic Properties

Alnico magnets are used in applications that require exceptional magnetic stability when operating at high temperatures as they lose less of their overall magnetic strength per increase in temperature than other permanent magnets.

They have the highest maximum operating temperatures of any permanent magnetic material, even up to 550? for some grades.

However, despite their resistance to high temperatures they are susceptible to demagnetization, so much so that forcing two Alnico magnets together in repulsion can permanently demagnetize both of them.

what are Samarium Cobalt magnets?

Samarium cobalt (SmCo) is a magnetic material made of an alloy of the rare earth element samarium and hard metal cobalt as well as traces of iron, copper, hafnium, zirconium, and praseodymium.

Like neodymium, samarium cobalt magnets are known as rare earth magnets as samarium is part of the same rare earth group of elements as neodymium.

Samarium cobalt magnets were developed in the early 1970s by the U.S.

Air Force Materials Laboratory and were then the strongest magnets available until the introduction of neodymium magnets approximately ten years later.

At the time of their introduction, they were revolutionary, tripling the strength of the strongest available magnetic material.

Samarium Cobalt magnets Manufacturing

Samarium cobalt magnets are typically manufactured by a method of reduction and melting followed by a process of bonding or sintering the raw material to form the magnet.

Sintering is the most common manufacturing method as described here.

Similarly to the process for manufacturing neodymium magnets the raw materials for producing samarium cobalt magnets are heated in an induction furnace and melted.

The liquid alloy is then poured into molds and cooled to form ingots.

Once the ingots are cooled they are broken down and milled to produce tiny micron-sized particles of samarium cobalt powder.

The powder is then pressed using one of two methods;

die pressing, where the powder is placed in a hard die and pressed or isostatic pressing where the powder is placed into a rubber die and pressed with equal pressure in all directions.

Isostatically pressed magnets generally have better magnetic characteristics while die pressed magnets can be created to smaller dimensions.

Once the powder is pressed it is sintered at a temperature up to 1250?C, fusing the powder into a solid.

The sintered material is then given a solution treatment at similar temperatures before being tempered between 700?C and 900?C and then cooled in the presence of an externally applied magnetic field.

Finally, the magnetic material is machined, ground and finished using water-cooled diamond-coated grinding machinery before being coated and magnetized.

Samarium Cobalt magnets Magnetic Properties

Samarium cobalt magnets are available in two types or grades, commonly referred to as series 1:5 and series 2:17.

Both series’ have high magnetic strength and have maximum energy products up to 35MGOe.

Although they are not as strong as neodymium magnets their major strength is that they can maintain their performance in temperatures up to 350?.

They are also extremely resistant to corrosion, even without coating.

However, because they contain cobalt, they are relatively expensive to produce.

Part of the content in this article is reproduced from other media for the purpose of transmitting more information and does not mean that this website agrees with its views or confirms the authenticity of its content. It shall not bear direct responsibility and joint liability for the infringement of such works.

If there is any infringement, bad information, error correction, and other issues in the content of this page, please contact us at info@albmaterials.com

Link to this article: https://www.albmagnets.com/blog/5-examples-of-magnetic-materials.html

How to choose and buy a strong neodymium magnet? ALBMagnets is a professional company for strong magnet design and manufacturing,

providing you with reliable N35, N38, N42, N52, N42SH and other grade super neodymium magnets and SmCo rare earth magnets.