401 Ryland St. Ste 200-A,

Reno, NV 89502

United States

E-mail: sales@albmaterials.com

- DA01 Neodymium Magnets, 5/8 inch dia. x 1/32 inch thick

- B884 Neodymium Magnets, 1/2 inch x 1/2 inch x 1/4 inch thick

- BCCA Neodymium Magnets, 3/4 inch x 3/4 inch x 5/8 inch thick

- NSW82 Steel Cups and Washers

- D603 Neodymium Magnets, 3/8 inch dia. x 3/32 inch thick

- BX021 Neodymium Magnets, 1 inch x 1/8 inch x 1/16 inch thick

- BX8C4-N52 Neodymium Magnets, 1 1/2 inch x 3/4 inch x 1/4 inch thick

- R-OD130H15ID110-N35 Neodymium Magnet, OD130xID110x15mm Ring Magnet

- D24 Neodymium Magnets, 1/8 inch dia. x 1/4 inch thick

- BCCC Neodymium Magnets, 3/4 inch x 3/4 inch x 3/4 inch thick

- BX042 Neodymium Magnets, 1 inch x 1/4 inch x 1/8 inch thick

- C-D5H5-N42UH Neodymium Magnet, 5x5mm Cylinder Magnet

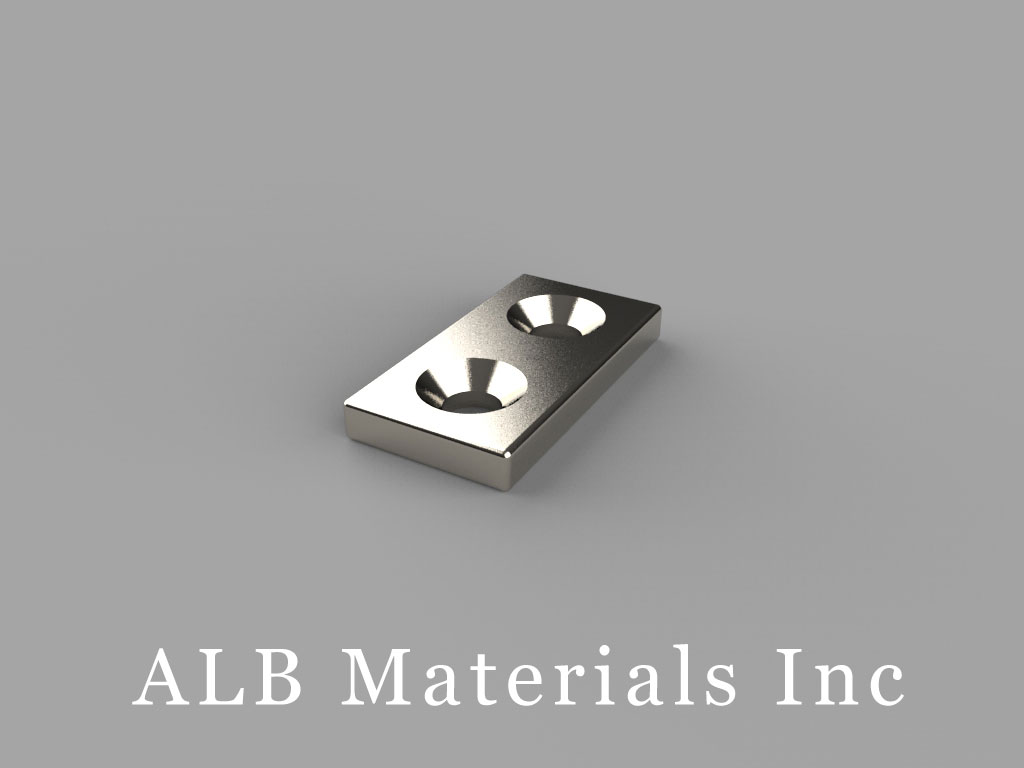

- MMR-A-ZC Rectangular Mounting Magnets

- WPH-SM Magnetic Hooks

- DX02-N52 Neodymium Magnets, 1 inch dia. x 1/8 inch thick

- R-OD22.5H3ID4(90deg)-N45 Neodymium Magnet, OD22.5xID4x3mm Ring Magnet

NdFeB Nd2Fe14B Permanent Magnets

NdFeB

Neodymium NdFeB Magnets Characteristics

NdFeB magnet has various grades: each grade has its own magnetic properties, relating to the strength of magnetic field output and resistance to demagnetization, ...

Structural use of Neodymium Iron Boron, NdFeB, magnets

There is a risk of chipping or breaking the magnets because all magnets are inherently brittle.

The Neo magnets are less brittle than SmCo.

It is advised to not put magnets in conditions of mechanical stress e.g. in load-bearing situations.

How to test real silver using neodymium magnets:

Send Us a Print or Ask a Question

I would like to join the mailing list to receive updates from ALB Magnets.

Attach Drawing:

Have Drawings & Need A Quote?

Send us your prints and specifications detailing your custom magnet application.

Neodymium Magnet NdFeB Magnet rare earth magnets

NdFeB magnets are available in both sintered and bonded forms.

Sintered NdFeB offers the highest magnetic properties (28 MGOe to 50 MGOe) while Bonded NdFeB offers lower energy properties.

NEODYMIUM IRON BORON MAGNETS

Known as the third generation of Rare Earth magnets, Neodymium Iron Boron (NdFeB) magnets are the most powerful and advanced commercialized permanent magnet today.

Since they are made from Neodymium, one of the most plentiful rare earth elements, and inexpensive iron, NdFeB magnets offer the best value in cost and performance.

Although bonded magnets do not possess magnetic properties as advanced as those of sintered magnets, they can be made in shapes and sizes that are difficult to achieve with sintering.

A variety of coatings can be applied to the magnets' surface to overcome the principal drawback of neodymium-based magnets, their tendency to corrode easily.

Neodymium Iron Boron Magnets - ALB Corporation

NdFeB magnet applications include high-performance motors, brushless DC motors, sensors, and magnetic resonance imaging equipment.

NEODYMIUM IRON BORON MAGNETS

THE HIGHEST ENERGY PRODUCT AVAILABLE

ALB is a preferred supplier of neodymium iron boron (NdFeB) or “neo” magnets for a variety of markets and applications.

NdFeB magnets offer the highest energy product of any permanent magnet material on the market today.

The various grades of ALB neodymium iron boron offer customers many options when selecting materials based on operating temperature and energy product requirements.

ALB NdFeB magnets provide a cost-effective solution for high-performance requirements.

ALB NdFeB products are used in a variety of applications including:

Spindle and Stepper Motors

Drive Motors in Hybrid and Electric Vehicles

Electric Wind Turbine Generators

Neodymium Iron Boron (NdFeB) Magnets Price

Neodymium-iron-boron (NdFeB) is commonly called neodymium.

It is often described as a ‘rare-earth magnet’ and is known to be the strongest and most powerful magnetic material.

It has a maximum energy product of 52 MGOe and was discovered in 1980.

The processes that relate to the performance of NdFeB have been systematically improved, resulting in an ever-higher maximum energy product.

Magnetic specialist, ALB, sells neodymium-iron-boron (NdFeB) magnets under the brand name ALB.

Today NdFeB is the most popular and commonly used magnetic alloy.

It should be known that the disadvantages of NdFeB are the low-temperature resistance, the mechanical brittleness, and the fact that the material is subject to corrosion,.

This means that it can’t be used for certain applications.

Despite this, NdFeB offers the highest available magnetic energy density.

It has a BHmax value of 33 to 52 MGOe.

Therefore, the far less magnetic material is needed compared to other magnetic alloys.

This explains the huge popularity.

NdFeB powder is extremely fine and in the dry state can ignite spontaneously.

For safety, it is important to be extra careful and take precautions when handling NdFeB powder.

Applications

Neodymium magnets, with their high strength and performance, are used in many applications.

Some of these applications include; Motors, Spindle drives of hard disks, Speakers.

NdFeB Magnets ALB

ALB magnets are produced on the basis of neodymium-iron-boron alloys and have the highest energy density available today. ALB alloys are Arc application with high energy density

Elevator motors

Automotive applications (e.g. electric power steering, sensors, etc.)

Scientific applications (wigglers, beam guiding systems, and undulators)

Aviation

Technical Specification

Magnets out of ALB are produced by sintering using powder metallurgical processes.

The excellent magnetic properties of ALB are traced to the strongly magnetic matrix phase Nd2Fe14B with very high saturation polarization and high magnetic anisotropy.

A ductile neodymium-rich bonding phase at the grain boundaries gives these magnets good magnetical properties.

Depending on the form, quantities, dimensions, tolerances, and magnetic properties the magnets are produced out of bigger (isostatically) pressed blocks or die-pressed.

The magnetic properties are influenced by the alloy composition and the pressing.

Different positions for the back pat method.

Three different processes are possible which are reflected in the alloy name with the letters HR, TP, or AP.

HR (High Remanence) refers to isostatically pressed magnets.

In die-pressed design, we differentiate between TP (Transverse-Pressed) and AP (Axial-Pressed)

When die-pressing, the powder particles are aligned by strong magnetic fields parallel (axial field for AP-grades) or perpendicular (transverse fields for TP-grades) to the direction of pressing depending on the geometry of the part.

Isostatically or transverse-field pressed parts to have about 5 to 8 % higher remanence compared to axial-field pressed magnets.

With the established grain boundary diffusion process the coercivity of such magnets can be increased up to a maximum of 600 kA/m (depending on the thickness of the permanent magnet).

Our ALB Alloys made of Neodymium-Iron-Boron

Developments in the processing and properties of NdFeb type

Three common fabrication routes can be used to categorize these NdFeB-based bulk magnets: sintering, polymer bonding, and hot deformation.

The composition, microstructure, and processing of NdFeB-type permanent magnets are all critical factors for the successful production of high-performance magnet components.

Three common fabrication routes can be used to categorize these NdFeB-based bulk magnets: sintering, polymer bonding, and hot deformation.

Generally, the former type of magnet has a high-energy product (30–50 MGOe), full density, and a relatively simple shape.

Bonded magnets have intermediate energy products (10–18 MGOe), lower density, and can be formed into intricate net shapes.

Hot deformed magnets possess full density, intermediate to high-energy products (15–46 MGOe), isotropic or anisotropic properties, and have the potential to be formed into net shapes.

This article discusses the critical issues of improved magnetic performance, environmental stability, net-shape formability, and magnetization behavior for the main categories of NdFeB magnets.

NdFeB magnet price

The nation exported NdFeB magnets to 104 countries in 2018, down from 109 the year prior.

The value of China’s NdFeB exports increased 14% and the sales-weighted average unit price increased 3%, from the US $49.14 per kilogram to US $50.40 per kilogram.

As we highlighted in a recent insight, China’s NdFeB permanent magnet production increased by 5% in 2018 while domestic NdFeB consumption increased by approximately 6%, keeping the market tightly balanced, as evidenced by price increases for all 31 NdFeB grades that we cover in 2018 versus the year prior.

Rare Earth Recap 2018: Global Production, Trade, and Prices

Nd2Fe14B magnet

The corrosion behavior of Nd2Fe14B and SmCo5 magnets

The purpose of this study is to investigate the corrosion behavior of a Nd2Fe14B magnet and a SmCo5 magnet in an oral environment.

The corrosion behavior of Nd2Fe14B and SmCo5 magnets

Rare earth magnets have corrosive problems associated with their use in prostheses in various fields including orthodontics.

The purpose of this study is to investigate the corrosion behavior of a Nd2Fe14B magnet and a SmCo5 magnet in an oral environment.

The relations among the attractive force changes, the released elements, the weight changes, and the anodic polarization measurements of the magnets were examined under immersions in 1% NaCl, 1% lactic acid, 0.05% HCl, 0.1% Na2S, and Greenwood's artificial saliva at 37 degrees C for forty-two days.

The results showed that the rare earth magnets underwent high corrosive assaults and large attractive force reductions by immersions in 1% lactic acid and 0.05% HCl.

The problem of corrosion of the magnets could be overcome by sealing them within laser-welded stainless steel capsules.

calculated Cu K-α diffraction pattern of Nd2Fe14B [19]. 3.2 – Coercivity mechanisms. One very important property of a permanent magnet.

Magnetic nanocomposite alloys developed from amorphous precursors by annealing often exhibit metastable transition phases that ultimately control the kinetics of the nucleation and growth of the desired RE{sub 2}Fe{sub 14}B-type phase.

It is thus important to understand the effect of starting composition on the formation of the metastable transition phases found in the nanocomposite system.

The relationships between composition and the nature of metastable phase formation in the low-boron content melt-spun nanocomposite alloy Nd{sub 2}[Co{sub 0.06}(Fe{sub 1{minus}x}Cr{sub x}){sub 0.94}]{sub 23.2}B{sub 1.48};(0{le}x{lt}0.09) were studied and compared with results of other authors.

The crystallization sequence undertaken by the quenched samples during annealing more » was followed by differential thermal analysis and x-ray diffraction.

Differences in the nominal starting boron: RE compositional ratio of the alloy may produce significant changes in the nature and stability of the metastable phases present in the system.

In general, a high compositional ratio (B:RE{approx}1{endash}4) promotes the initial formation of Fe{sub 3}B and complex boron-rich intermetallic phases such as the cubic Nd{sub 2}Fe{sub 23}B{sub 3}, the hexagonal NdFe{sub 12}B{sub 6} and the cubic Y{sub 3}Fe{sub 62}B{sub 14}-type phases in the quenched material, while a low compositional ratio (B:RE{lt}0.5) is favors the formation of {alpha}-Fe and a 2-17-type phase.

It is suggested that the focus of further studies done to optimize the performance of these nanocomposite alloys should be on the effect that alloying additions have upon the metastable phases, and not on the final equilibrium phases.

Nd2Fe14B magnet · Institute/Department name Materials engineering department

Nd2Fe14B magnet Grade: N35, N38, N40, N45, N48, N50, N54, N42, N52.

Neodymium Iron Boron (NdFeB) is the strongest permanent magnet material available.

It can be used at temperatures below 130 °C and can be used (subject to selecting the correct grade) up to +220 /230 °C.

The NdFeB magnets are the first choice for many applications as they offer the greatest performance with the smallest volume.

Neodymium Iron Boron magnets exist in a variety of grades.

These grades not only vary in magnetic output performance but also vary with a temperature rating.

N50 is the highest readily available grade of NdFeB.

Crystal structure and magnetic properties of Nd2Fe14B

Rare-Earth Permanent Magnets: New Magnet Materials And Applications.

Crystal structure and magnetic properties of Nd2Fe14B powder prepared by using high energy milling from elements metal Nd, Fe, B powders

The Nd2Fe14B powder has been made by using High Energy Milling (HEM) from mixed metal powders Iron (Fe), Neodymium (Nd), and Boron (B).

The Nd, Fe, and B powders were mixed according to stoichiometric composition (atomic ratio Nd: Fe: B = 2: 14: 1), and milled and milling time was varied in 10, 20, and 40 hours by using HEM.

Toluene liquid was used as milling media to protect metal powders from oxygen.

The measurement result of x-ray diffraction shows that the optimum Nd2Fe14B phase already formed about 69,46% after milling 40 hours with crystallite size about 25.64 nm.

The magnetic properties of milled powders were measured by using VSM at room temperature.

The highest value of magnetic properties are obtained at powder milled in 40 hours, at this condition, it is obtained Ms = 122 emu/g, Mr = 81 emu/g, Hc = 5.54 kOe, and BHmax = 11.01 MGOe.

ndfeb permanent magnets

NdFeB permanent magnets are essential for modern-day technology thanks to their excellent magnetic properties.

neodymium block magnets

Buy very powerful Block Magnets Neodymium NdFeB

Block Magnets Neodymium. They are powerful neodymium magnets capable of supporting clamping forces of up to 200kg.

Neodymium magnetic blocks, thanks to their holding and separating force, are used to manufacture magnetic separators for all types of industrial sectors such as aerospace, medicine, renewable energy, and the automotive industry, Microphones, Hospital machines, among others.

Where can I buy Neodymium magnetic blocks?

ALB is an online factory specializing in powerful neodymium magnets with over 30 years of experience in the industry.

They have the largest magnet factory in Spain and one of the largest factories in Europe.

In its wide product catalog, you can find a neodymium magnet n52 to a large neodymium super magnet for all industrial sectors.

If you need information, you can contact ALB and buy neodymium blocks at very competitive prices.

You can buy Neodymium magnets in magnetic block form at albmagnets.com

At alb magnets, you can buy neodymium magnetic blocks in different qualities, dimensions, and quantities.

They offer their products to both private and corporate customers and can help you through the entire product selection process.

Thanks to more than 30 years of experience in the sector and their large stock, they can offer the best prices to all industrial sectors.

You can contact us by phone or email.

Global provider

150 workers and 3 production centers.

Part of the content in this article is reproduced from other media for the purpose of transmitting more information and does not mean that this website agrees with its views or confirms the authenticity of its content. It shall not bear direct responsibility and joint liability for the infringement of such works.

If there is any infringement, bad information, error correction, and other issues in the content of this page, please contact us at info@albmaterials.com

Link to this article: https://www.albmagnets.com/blog/ndfeb-nd2fe14b-permanent-magnets.html

How to choose and buy a strong neodymium magnet? ALBMagnets is a professional company for strong magnet design and manufacturing,

providing you with reliable N35, N38, N42, N52, N42SH and other grade super neodymium magnets and SmCo rare earth magnets.