401 Ryland St. Ste 200-A,

Reno, NV 89502

United States

E-mail: sales@albmaterials.com

- R84X0 Neodymium Magnets, 1/2 inch od x 1/4 inch id x 1 inch thick

- D-D20H1-N50 Neodymium Magnet, 20x1mm Disc Magnet

- BY08Y0 Neodymium Magnets, 2 inch x 1/2 inch x 2 inch thick

- DA4-N52 Neodymium Magnets, 5/8 inch dia. x 1/4 inch thick

- BY066 Neodymium Magnets, 2 inch x 3/8 inch x 3/8 inch thick

- D301 Neodymium Magnets, 3/16 inch dia. x 1/32 inch thick

- B30x10x3mm Neodymium Magnet, 30 x 10 x 3mm Block Magnet

- B84H1 Neodymium Magnets, 1/2 inch x 1/4 inch x 1/10 inch thick

- D-D18H6-N48 Neodymium Magnet, 18x6mm Disc Magnet

- B15x6x5mm Neodymium Magnet, 15 x 6 x 5mm Block Magnet

- DY0X8 Neodymium Magnets, 2 inch dia. x 1 1/2 inch thick

- D6x4mm Neodymium Magnet, 6 x 4mm Disc Magnet

- D20x20mm Neodymium Magnet, 20 x 20mm Cylinder Magnet

- BCCA Neodymium Magnets, 3/4 inch x 3/4 inch x 5/8 inch thick

- DX0H2 Neodymium Magnets, 1 inch dia. x 2/10 inch thick

- DX07 Neodymium Magnets, 1 inch dia. x 7/16 inch thick

Ceramic Magnet Grades

ceramic magnet grades

GRADES OF FERRITE MAGNETS

There are currently 27 grades of permanent ferrite magnets commercially available all of which have different ferromagnetic properties.

Ferrite magnets, also known as ceramic magnets, are commonly used in electric motors and generators due to their good resistance to demagnetization – they have high intrinsic coercivity!

Did you know? There are 27 different grades of permanent ferrite magnets commercially available.

The chemical compound of ferrite magnets is SrO-6 (Fe2O3), a combination of strontium carbonate and iron oxide;

some grades also include other chemicals such as cobalt and lanthanum to improve magnetic performance

Previously, grades of ferrite magnets were labelled with the letter ‘C’ then a number, for example, C1, C2, C3.

This system has now been superseded by a similar one with all grades beginning with the letter ‘Y’ followed by a number or a series of numbers and letters.

The numbers following the letter define the maximum energy product for the magnet, any letters following the numbers are there to differentiate further between different grades with different characteristics.

The most popular grade of permanent ferrite magnets is Y30, you can buy these right now in the block, disc, ring, hook, channel, or pot form from the albmagnets.com shop.

The most common grades of ceramic magnets are 1, 5, and 8 (on a scale of 1-8) Ceramic magnets are limited to simple shapes because of their manufacturing process. It's considered a relatively brittle magnet.

Ceramic Magnets

What are Ceramic Magnets?

Ceramic magnets are used in magnetic assemblies designed for lifting, holding, retrieving, and separating.

They’re made of strontium carbonate and iron oxide.

They’re readily available and less expensive than other magnets.

They’re made using the pressing and sintering processes and come in different grades.

The most popular grades are 1, 5, and 8.

Ceramic is also known as Ferrite, and these magnets are known for their good balance of magnetic strength, resistance to demagnetization, and economy.

They’re considered the most widely used magnet in today’s industry.

Ferrite ceramic magnets are usually non-conductive ferromagnetic ceramic compounds derived from iron oxides such as hematite (Fe2O3) or magnetite (Fe3O4) as well as oxides of other metals.

Ceramic magnets are part of the permanent magnet family, which means they have a high coercive force and therefore hold their magnetic field well (under a proper application) after they are magnetized.

Attributes of Ceramic Magnets:

Less expensive material than alnico and rare earth magnets

Lower service temperature than alnico magnets, greater than rare earth magnets

The most common grades of ceramic magnets are 1, 5, and 8 (on a scale of 1-8)

Ceramic magnets are limited to simple shapes because of their manufacturing process

It’s considered a relatively brittle magnet

What Types of Ceramic Magnets are Out There?

As you can imagine, ceramic magnets have come in several forms.

These ferrite magnets have a wide variety of applications as well: Speaker Magnets, DC Motors, Sweepers, Magnetic Separators for ferrous materials, Automotive Sensors, MRI’s, Reed Switching, Hall Effect Devices, in Assemblies.

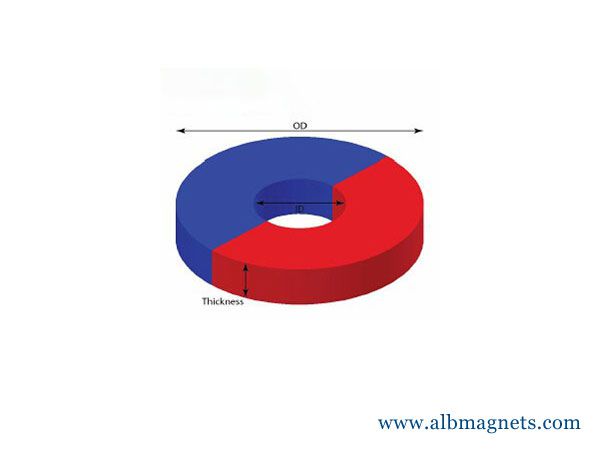

Here at albmagnets.com, we offer ceramic disc magnets, ceramic ring magnets, and ceramic block magnets.

We also have a ceramic magnet with a hole.

This ceramic magnet was formed this way so that it can be mounted wherever you would like it.

It has exceptionally strong holding power.

Ceramic Magnets Grade 5 & 8:

Ceramic Grades 5 & 8 have become some of the most widely specified magnetic materials.

Low cost, lightweight, a relatively high energy product, and good resistance to demagnetization account for the widespread use of Ceramic magnets.

Ceramic Magnets Grade 1

This small magnetic is offered in a ring form and can be used in the tightest spaces and applications.

It’s great for motors, holding magnets, and other devices.

CERAMIC MAGNETS

FOR THE STRONGEST CERAMIC MATERIAL AVAILABLE

ALB is a preferred supplier of ceramic permanent magnets.

Also known as “hard ferrites,” ceramic magnets provide high resistance to corrosion at economical price points.

ALB offers five different grades of ceramic magnets, including Ceramic 8B, the strongest ceramic material available.

The high electrical resistivity of this material is another benefit, providing superior opposition to the flow of electric current.

Features of ALB Ceramic Magnets

A cost-effective option for medium- and high-volume applications

High resistance to demagnetization and excellent thermal stability

Available as isotropic or anisotropic

Various grades with (BH)max ranging from 1.05 to 4.0 MGOe

Very high electrical resistivity to reduce eddy current losses in electrical machines

Superior corrosion resistance

We stock ceramic block magnets in Grade 8, magnetized through the thickness.

Machining and tolerances

Machining must be performed with a diamond wheel, preferably before magnetization.

Standard tolerances are +/-.004” for ground dimensions and +/- 2% of feature size for sintered dimensions.

Due to their brittle nature, these magnets will not withstand impact or flexing.

They are also not recommended to be used as structural components in assemblies.

Ceramic magnets are chemically inert non-conductors, which is a benefit in many applications but eliminates the use of the EDM process to produce samples or special shapes.

Temperature constraints and methods of magnetization

Due to Ceramic’s positive temperature coefficient of Hci high temperatures are not generally a major concern with respect to irreversible magnetic loss.

Low temperatures, however, pose a much greater risk for permanent demagnetization.

For example, a ceramic 5 grade with a permeance coefficient of 1 will start to experience permanent losses below -20°C.

Magnetization

Isotropic ceramic grades can be magnetized in any direction, while anisotropic grades have a preferred direction of magnetization and will only meet their full magnetic potential when magnetized along the “easy axis.”

Gauss Calculations of Ceramic Magnets

Grades of Ferrite

The Ferrite magnets have had trade names but are now following the Chinese nomenclature

The first ferrite magnets tended to have names such as Fer 3 or Feroba 3.

This is a trade name that is no longer used.

Then the naming of ferrite started with the letter “C” e.g. C5 and C8.

Although this is still used in the USA and UK, the range of grades named is limited.

Since most production of ceramic hard ferrite magnets is in China (which is where our production facility is based), Chinese nomenclature has taken over and is popularly used in the UK and Europe with greater acceptance in the USA as well (the grades start with the letter “Y”.Fer 3 and Feroba 3 is now called Y30H-1.

Ferrite C8 is also known as Y30H-1.

Fer 2 and Feroba 2 is now called Y30.

Ferrite C5 is also known as Y30.

Most ferrite magnets are known either by their C names or by the newer Y names.

Other names exist for ferrite grades e.g.

HF26/18 (which is Y30) but this is a European naming convention and is not commonly used outside mainland Europe.

We can supply virtually any grade of ferrite permanent magnet to your size requirements.

The ferrite magnets are generally anisotropic (they have a preferred direction of magnetization locked within their structure allowing better magnetic performance);

isotropic versions (can be magnetized in any direction but has lesser performance) also exist e.g. C1, Y10T, and HF8/22.

The Chinese ferrite magnet nomenclature system has a structure to it.

Y is an identifier for Ceramic Magnet / Hard Ferrite Magnet.

The number following it is linked to the BHmax Energy product.

Any letter after the number is an additional grade identifier.

There are 27 grades of ferrite magnet.

Below is an example BH curve for Ferrite C5 (Y30).

Ferrite C5 and Ferrite C8 are the most popular grades of hard ferrite (ceramic) magnets.

Nomenclature of Ferrite (Ceramic) Magnet grades

Chinese Standard - Commonly used globally, especially in the UK and EU.

Neodymium Magnet Grades

A Neodymium (Rare Earth) magnet Grade (for example, N42) is an accurate guide to the strength of a magnet.

Generally speaking, higher grade numbers indicate a stronger or more powerful magnet.

The number comes from an actual material property, the Maximum Energy Product of the magnet material, expressed in MGOe (Mega Gauss Oersteds).

It represents the strongest point on the magnet’s Demagnetization Curve or BH Curve.

The pull force of a magnet varies with the grade of ‘N’ number.

As the Grade increases, so does the magnet's pull force.

However, shape, thickness, operating temperature, and proximity to other magnetic material will also impact the magnet's performance.

Higher grade magnets are typically used where space is restricted and it would be difficult or impossible to use a larger, more powerful magnet.

Letters after the Grade, for example, N42SH, refer to heat tolerance, or the temperature at which the magnet will become unoperational.

N30EH has the highest heat rating and remain effective at temperatures up to 392°F or 200°C.

ALB Magnets has a range of Neodymium Magnets in various grades from N30 to N52 and with heat tolerances from 176°F to 392°F (80°C to 200°C).

magnetic-grade-chart

Cast / Molded NdFeB suspended in an epoxy resin, Lower strength than SmCo.

Requires mold tooling. Hard and highly brittle. High operating temperatures. Highly corrosion resistant. Weaker than NdFeB Magnets.

Ferrite magnet powder suspended in rubber a rubber resin.

Corrosion-resistant, Magnetic field is easily disrupted and changed by stronger magnets.

Terms and Definitions

Br (KG) - "Residual Flux Density Measured in Kilo Gauss"

This is a measurement of the material's ability to retain a magnetic field after being magnetized.

For Example, Iron can be temporarily magnetized but will lose the majority of its magnetic strength when the external field is taken away.

This is because Iron has a low Residual Flux Density.

HcB (Koe) - "External Force Required to Demagnetize Measured in Kilo Oersteds"

This is a measurement of the material's ability to resist external and internal magnetic forces without being changed.

For Example, Flexible/rubberized magnets have a lower HcB and therefore can be easily demagnetized/remagnetized by a stronger neodymium magnet.

Neodymium magnets will lose about 1% of their magnetic strength every 10 years due to self demagnetization.

BHMax (MGOe) - "Maximum Energy Product Measured in Mega Gauss Oersteds"

This is a direct measurement of a material's maximum magnetic strength after the magnet is fully saturated "charged" by an external magnetic field.

BHMax is the best indication of a given material's attractive power.

Tmax (Maximum Operating Temperature) - "Measured in Celsius / Fahrenheit"

Heating a magnet above its maximum operating temperature will cause it to permanently lose its magnetism until it is remagnetized by a strong external field.

Heating the material close to the maximum operating temperature (usually within the 20% range) will cause the magnet to temporarily lose its magnetic strength until it cools.

Part of the content in this article is reproduced from other media for the purpose of transmitting more information and does not mean that this website agrees with its views or confirms the authenticity of its content. It shall not bear direct responsibility and joint liability for the infringement of such works.

If there is any infringement, bad information, error correction, and other issues in the content of this page, please contact us at info@albmaterials.com

Link to this article: https://www.albmagnets.com/blog/ceramic-magnet-grades.html

How to choose and buy a strong neodymium magnet? ALBMagnets is a professional company for strong magnet design and manufacturing,

providing you with reliable N35, N38, N42, N52, N42SH and other grade super neodymium magnets and SmCo rare earth magnets.