401 Ryland St. Ste 200-A,

Reno, NV 89502

United States

E-mail: sales@albmaterials.com

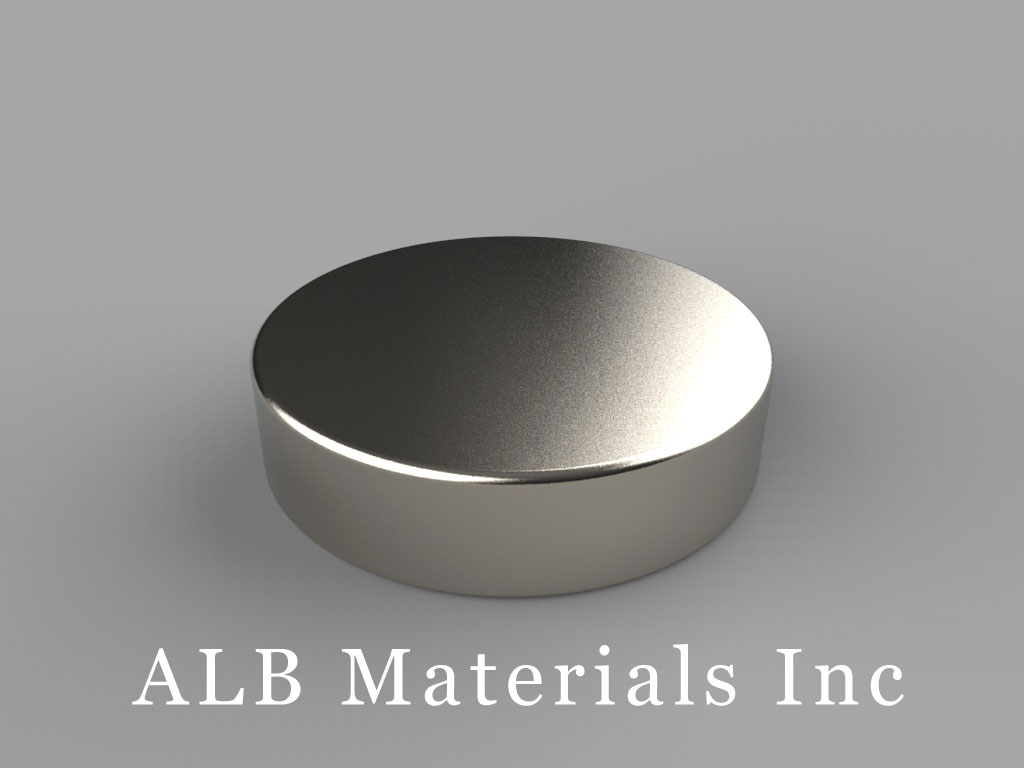

- D-D20H4-N42 Neodymium Magnet, 20x4mm Disc Magnet

- B-W10H10L10-N42 Neodymium Magnet, 10x10x10mm Block Magnet

- DFY8 Neodymium Magnets, 15/16 inch dia. x 2 1/2 inch thick

- BX8C1 Neodymium Magnets, 1 1/2 inch x 3/4 inch x 1/16 inch thick

- SB664-OUT Neodymium Magnets, 3/8 inch length x 3/8 inch width x 1/4 inch thick, with step OUT

- RX054 Neodymium Magnets, 1 inch od x 5/16 inch id x 1/4 inch thick

- BY0Y0C Neodymium Magnets, 2 inch x 2 inch x 3/4 inch thick

- B-W2.8H1.9L10-N50BNi Neodymium Magnet, 10x2.8x1.9mm Block Magnet

- D5H2 Neodymium Magnets, 5/16 inch dia. x 2/10 inch thick

- D1A Neodymium Magnets, 1/16 inch dia. x 5/8 inch thick

- D-D23.3H20-N48M Neodymium Magnet, 23.3x20mm Disc Magnet

- D-D9H1-N50 Neodymium Magnet, 9x1mm Disc Magnet

- D60x25mm Neodymium Magnet, 60 x 25mm Disc Magnet

- DF5 Neodymium Magnets, 15/16 inch dia. x 5/16 inch thick

- R-OD16.6H5ID3-N48 Neodymium Magnet, OD16.6xID3x5mm Ring Magnet

- XLTK-BLK Magnetic Thumbtacks

2 Neodymium Magnets

2 neodymium magnets

1/2 x 1/8 Inch Strong Neodymium Rare Earth Disc Magnets

total element neodymium disc magnets: 1/2" Diameter x 1/8" Thickness. Wholesale/volume discounts available. Free US shipping $10+.

All orders $10+ ship free within the United States.

Free 30 Day Returns

Return shipping is free when you choose to receive store credit.

Same Day Shipping

All orders placed before 2 pm MST on weekdays ship the same day.

* Customers must select the Standard Shipping option during checkout in order to receive Free Shipping.

If you select Priority or Overnight Shipping additional charges will apply.

Not valid on international shipments.

1/2 x 1/8 Inch Strong Neodymium Rare Earth Disc Magnets N48 (30 Pack)$16.99

2-lb Pull NICKEL-PLATED NEODYMIUM MAGNETS

Our each is a pack of (6) shiny nickel-plated neodymium magnets that each measure 1/2” dia x 1/8” thick, and have a 2-lb pull.

$3.25 EACH

Killer Magnet

What is a killer rare earth magnet? Well, once upon a time, a copywriter put this little magnet next to his computer monitor and got really pretty, wavy, aurora-like effects.

And then got a new monitor! Don't try this at home.

Our shiny, silver-colored 1" x 1" x 1/2" neodymium magnet looks innocent, but is industrial strength, pulling something like 25 lbs with enough strength left over to erase all your credit cards.

And wreak havoc with your monitor.

STRONG RARE EARTH MAGNET

And wreak havoc with your monitor.

$11.50 EACH

A Real Grabber

Okay, it isn't the cheapest magnet in the warehouse - but we pulled about 35-40 pounds with this 4-7/8" x 1" x 3/4" ceramic magnet, and we think it's a bargain.

It has a 6" bracket with mounting holes on 5-1/2" centers, plus a 1/2" ID eyehook bolted into the center of it.

It's all set to troll the bottom of the lake next time your filing cabinet falls overboard.

PICK-UP BAR MAGNET

It's all set to troll the bottom of the lake next time your filing cabinet falls overboard.

$8.95 EACH

RARE FIND!

Rare earth magnets are usually killers for their size, and these thick nickel neodymium discs are no exception.

The price, on the other hand, for (3) 7/16" dia x 1/4" 5-lb lift or (2) 15/32” dia x 3/16” 8-lb lift magnets each stored on a 2" dia steel disc, is a rare exception.

NEODYMIUM MAGNETIC DISCS 5-LB

RARE FIND!

Rare earth magnets are usually killers for their size, and these thick nickel neodymium discs are no exception.

The price, on the other hand, for (3) 7/16" dia x 1/4" 5-lb lift or (2) 15/32” dia x 3/16” 8-lb lift magnets each stored on a 2" dia steel disc, is a rare exception.

$3.45 EACH

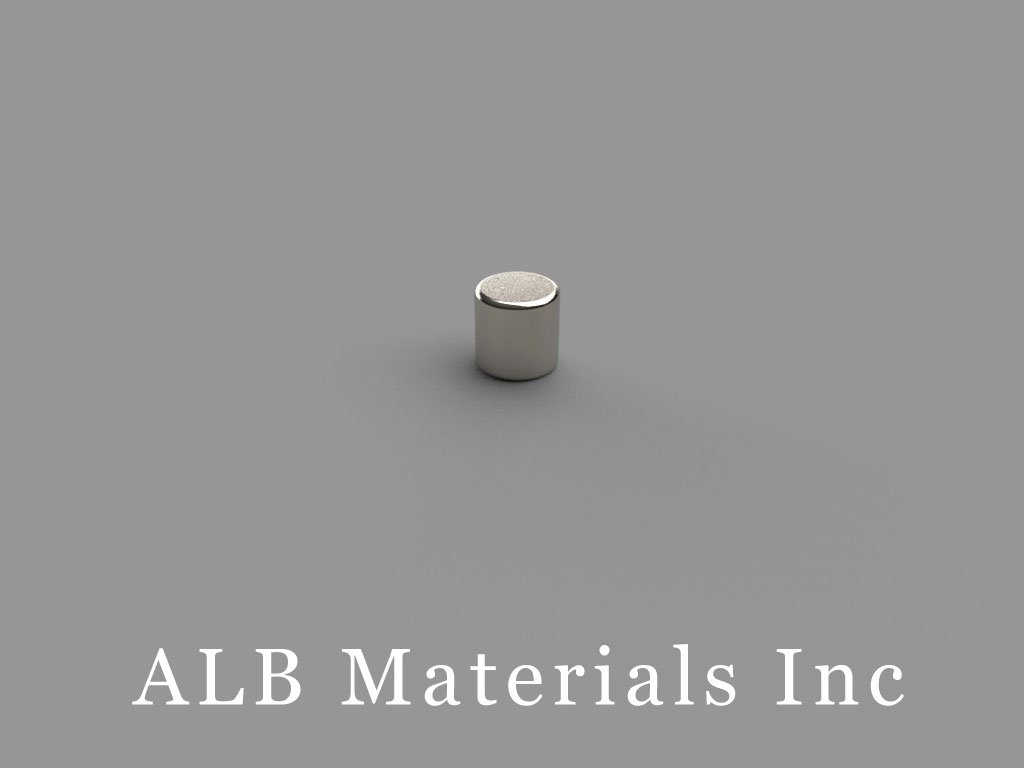

Neodymium Column

We're liking this little plated N45 neodymium magnet because it will stand on end and stick out very prettily on the ice box.

Measures 1" tall x 1/4" square with a hefty, for its size, 3-1/2 lb pull, 13,800 gausses.

(Will also lie down on its side, of course, because everybody does.)

COLUMN-SHAPED NEODYMIUM MAGNET

Neodymium Column

We're liking this little plated N45 neodymium magnet because it will stand on end and stick out very prettily on the ice box.

Measures 1" tall x 1/4" square with a hefty, for its size, 3-1/2 lb pull, 13,800 gausses.

(Will also lie down on its side, of course, because everybody does.)

$2.15 EACH

How Neodymium Magnets are Made

The basic compound for most Neodymium magnets is Nd2Fe14B. In practice, the actual chemical reaction used can be more complicated.

How Sintered Neodymium Magnets are Made

We describe the steps involved in manufacturing neodymium magnets, with some notes on what this means for practical magnet users.

1. Prepare Materials for the Reaction

The basic compound for most Neodymium magnets is Nd2Fe14B. In practice, the actual chemical reaction used can be more complicated. A commonly used reaction is:

57 Fe + 8 B + 10 Fe2O3 + 7.5 Nd2O3 + 52.5 Ca -> Nd15Fe77B8 + 52.5 CaO

Vacuum Induction Furnace

Note that the powder formed by this reaction is slightly different than the Nd2Fe14B ratio. Magnets are often made both Nd-rich and B-rich, where finished magnets typically contain non-magnetic bits of Nd and B in the grain, within which are highly magnetic Nd2Fe14B grains.

For higher temperature magnet grades, additional elements are added. When small amounts of Iron (Fe) are replaced with Cobalt ( Co ), the properties improve at elevated temperatures, but the intrinsic coercivity decreases. If small portions of Neodymium ( Nd ) are replaced with Dysprosium ( Dy ), the intrinsic coercivity is improved, but the maximum energy product ( BHmax, a good measure of a magnet's strength) decreases. It is common to use both Co and Dy together.

2. Melting

The chemical reaction described above occurs in a vacuum induction furnace. The products are heated by creating electrical eddy currents through it, all in a vacuum to keep contaminants out of the reaction.

3. Milling

Jet milling turns the resulting material into a powder with very small particle size. The average particle size is on the order of 3 micrometers.

4. Pressing

Pressing Steps

The powder is pressed together to form a solid that has a preferred magnetization direction. In a technique known as die-upsetting, the powder is pressed with a die into a solid at elevated temperatures of about 725°C. The solid is then placed in a second die, where it is compressed to a wider shape that's about half it's original height. This aligns the preferred direction of magnetization parallel to the pressing direction. For some shapes, there are methods that include a fixture that generates a magnetic field during pressing to align the particles.

5. Sintering

Sintering is a common process in powder metallurgy. The material is compressed at elevated temperatures (as high as 1080°C) below the material's melting point until its particles adhere to each other.

6. Machining

The sintered magnets are cut to the desired shape using a grinding process. Less commonly, complex shapes are made with electric discharge machining (EDM). Because of the high material cost, material losses due to machining are kept to a minimum. No effective means of recycling waste has been developed.

7. Plating

The individual magnets are electroplated with three layers: nickel, copper, and nickel. This is necessary because un-plated neodymium magnets are highly prone to corrosion, and will quickly lose their magnetic properties in the presence of moisture.

8. Magnetization

At this point, the magnets have a "preferred" direction of magnetization, but they are not magnetized. They are placed in a fixture that will expose the magnet to a very strong magnetic field for a brief moment. It's basically a big coil of wire surrounding the magnet(s). The magnetizing equipment uses banks of capacitors and a really huge voltage to get such a strong current for a brief instant.

9. Inspection

The quality of the resulting magnets is inspected for a variety of properties. A digital measuring projector verifies the dimensions. A coating thickness measurement system using x-ray fluorescence technology verifies the thickness of the plating. Periodic testing in salt-spray and pressure-cooker tests also verify the performance of coatings. A hysteresis graph measures the BH Curve of magnets, which confirms that they are fully magnetized as expected for the magnet's grade.

What all this means for users of neodymium magnets

A DY02 magnet with some of the nickel plating scraped away, revealing the raw NdFeB magnet underneath

Neodymium magnets are formed by powder metallurgical methods. Their mechanical properties more closely resemble ceramic, rather than metal. They are not easily machined, and we don't recommend trying to machine them. See our FAQ for more details.

Neodymium magnets are very hard and brittle. Despite the metallic appearance of their nickel plating, they are not as strong as steel. If subjected to sharp impacts, such as allowing them to slam into one another, they can easily crack or break. Care and proper handling are important.

We don't recommend press-fitting neodymium magnets. Magnets are often glued into a pocket that is slightly larger than the magnet, rather than press-fitting.

We don't recommend using a threaded magnet. While it's technically possible to cut threads, they don't hold up well under torque. A magnet attached to a part with steel threads works better, as some of our Mounting Magnets.

Neodymium magnets can't be made into very complex shapes that materials like steel or aluminum allow. It's best to try and design part complexity into other parts, and use more simple shapes in your magnets.

If you are looking for a particular size or shape that we don't offer as a stock magnet, ask us about custom magnets.

How to Separate Strong Magnets

here using our magnet splitter is good instruction for magnets in the 1 to the 2-inch size range.

Neodymium magnets pull towards each other with a strong force.

Neodymium magnets are strong. Really strong. If you have never handled neodymium magnets before, you will be surprised at their remarkable strength. They're not the ceramic magnets you find at craft stores.

Whether talking about relatively small magnets like 1/4" diameter D41 discs, or monstrously big block magnets like our BX8X8X8, separating these magnets can prove to challenge to those without experience.

Here, we share some of our strategies and tips for separating strong neodymium magnets.

The Basic Idea

Neodymium magnets pull towards each other with a strong force. If you try pulling two magnets directly apart, you need quite a bit of force to pull them apart. To separate one magnet from another, you'll need to pull with a force equal to the listed Pull Force Case 1 number.

This can be difficult if the magnet is strong, or if there isn't much area to grab onto the magnet. Most methods of separating these magnets do two things:

They provide more leverage and/or a better way to grip the magnets

They move the magnets apart laterally (sideways), which requires less force

Small Magnets

Small magnets can be separated by hand, usually without any mechanical aid. Magnets with listed Pull Force Case 1 values of about 5 lb or less fall into this category. The key is to slide one magnet off the stack with lateral motion, as shown in the video of D42 magnets below.

The video for our B333 cubes is also instructive.

If you are having trouble, consider using the edge of a desk to help remove the top magnet off a stack, as shown in the video below of our D63 disc magnets.

Medium-Sized Magnets

Medium-sized magnets might range from 10 to 50 lb in their listed pull force numbers. While they can be separated by hand, it can help to use some kind of leverage such as the edge of a table.

The DX04 video below shows that it's easier to separate two magnets when a small plastic spacer is kept between them. Once the spacer is removed, it is much more difficult to separate by hand. The video shows magnets separated using the edge of a desk and with our MAGS1 Magnet Splitter.

The RX038DCB-N52 is a stronger magnet, but we use the same techniques.

Be careful handling magnets in this strength range. It can be easy to pinch your skin when handling such magnets. Also, consider wearing safety glasses with magnets this size. If allowed to collide, small chips can fly off the magnets.

Big Magnets

We offer a number of really big magnets that are, quite frankly, challenging to handle. Here we show our BX8X8X8 1.5" cube magnet being separated using our MAGS1 magnet splitter. With a spacer between them, we can separate these magnets by hand, though I wouldn't recommend this without experience.

The method shown here using our magnet splitter is good instruction for magnets in the 1 to the 2-inch size range. We offer our MAGS1 magnet splitter for sale on our website. For those who prefer to make their own, we even have an article posted about how to Build Your Own Magnet Separator Tool.

We have not yet posted videos for larger magnets. For 3" magnets, we usually separate them with more than one person involved to stay safe. Be careful out there!

WARNING: Neodymium Magnets are Brittle and Fragile!

Neodymium magnets are made of brittle material. Don't let the shiny nickel plating fool you -- these magnets are not as strong as steel. They are more like a brittle ceramic. If you let two magnets slam together, they can crack and break. This is true for magnets large and small. Even small D41 magnets can crack if you let them fly together.

The video below includes some high speed photography showing what happens when strong magnets collide.

More examples of the Video Summary Page

Looking for an example of how to handle your specific magnet? Many of our product pages include a video of that magnet under the "Video" tab. For a list of magnets that include videos, check out our Video Summary Page. Don't see one you're looking for? Suggest our next magnet video!

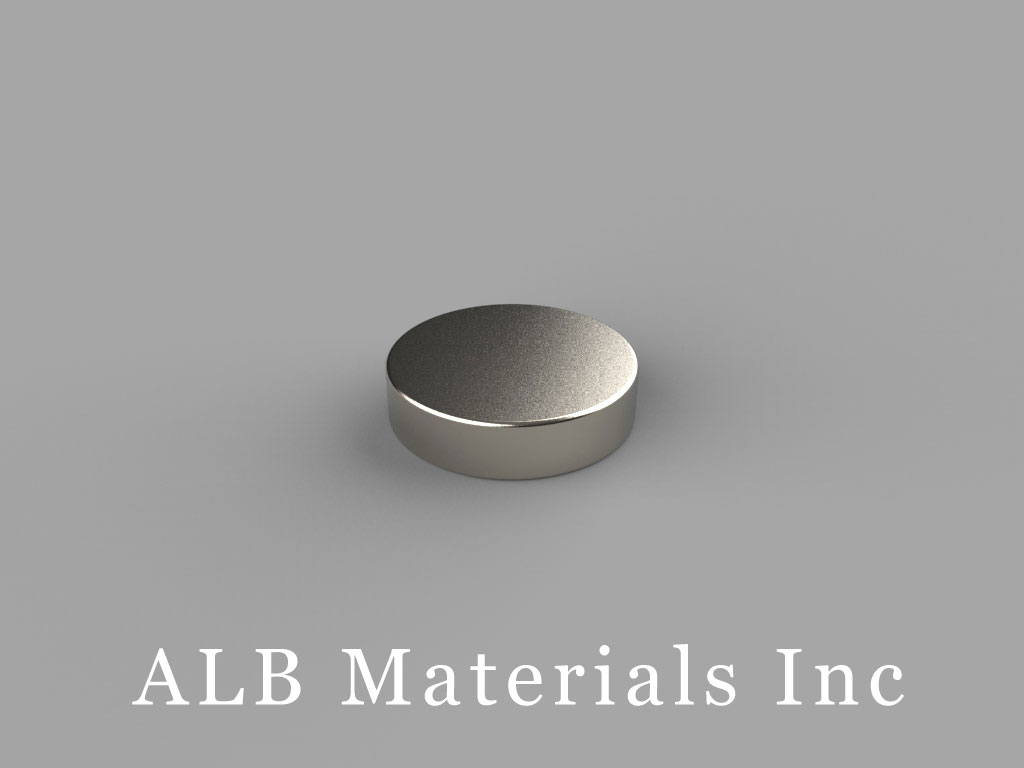

Neodymium Magnet, 1/2 in. Disc

Neodymium magnets also contain Iron and Boron, making them some of the strongest magnets in the world.

1/2" x 1/8" Disc, 2/pkg.

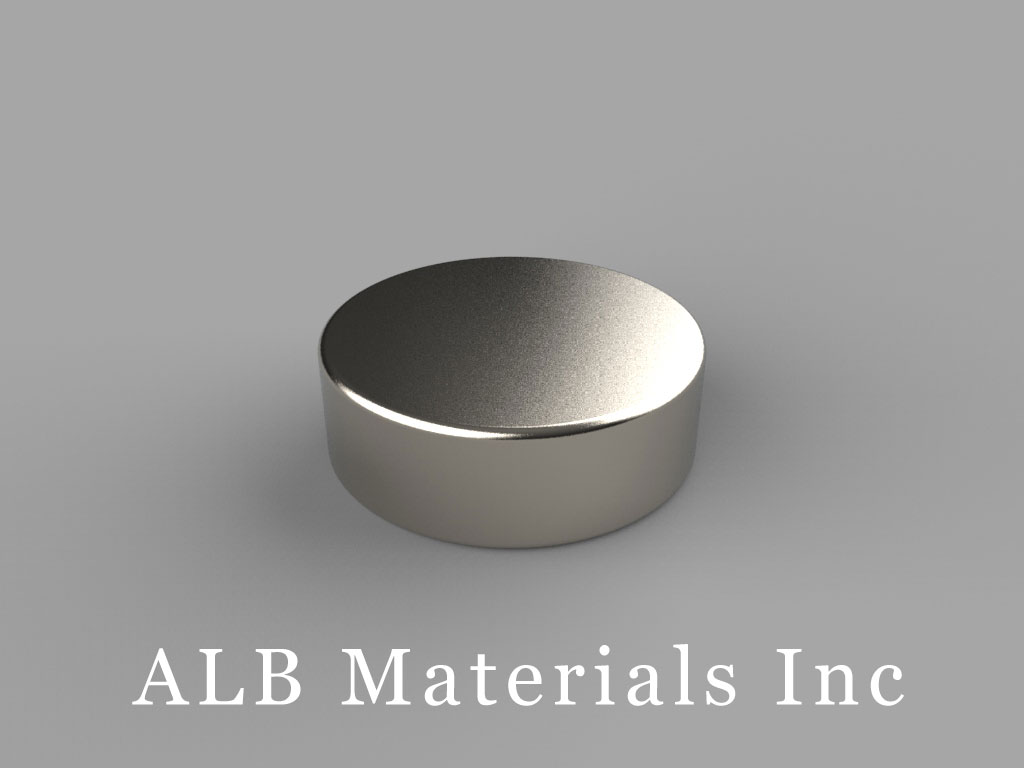

Neodymium Magnet, Round 1/2 x 1/4"

Round Neodymium Magnet, 1/2 x 1/4" is rated 1.5 out of 5 by 2.

World's most powerful permanent magnet, many times the strength of ordinary or other rare-earth magnets.

Made of 25% neodymium, 70% iron, and 5% boron.Round.

Size, 1/2 x 1/4".

Includes an instruction sheet with suggested experiments.

Price$, In stock and available to ship.

Rated 2 out of 5 by Lucy from Use carefully! I used these magnets to separate iron from breakfast cereal and it worked great, however, the magnets chip very easily.

I'm not comfortable with the idea of small pieces of a powerful magnet being left behind or scattered in the classroom.

Perhaps they should be wrapped in something to prevent this from happening?

Rated 1 out of 5 by Neto from One-time use only Students used them once and they chipped.

I have never seen magnets chip so easily.

Neodymium Magnets for Sale

From $0.08 Shop

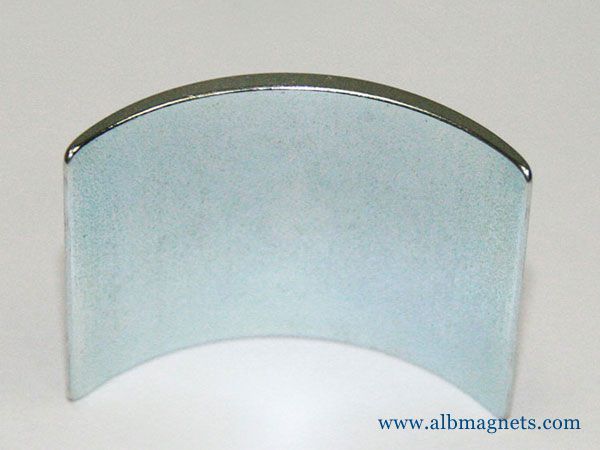

Neodymium Discs are made in a variety of sizes and grades to meet all types of applications.

Discs, also known as Plugs, can be used in applications like switches, electronics, and miniaturizations.

Block Magnets have straight sides where the opposite sides are parallel to each other.

Depending on the application, you may need a Neodymium Ring Magnet or a disc magnet with a hole in it.

Although the hole can be placed at nearly any position on the disc.

Neodymium Countersunk Rings and Countersunk Ring Magnets are made in a variety of sizes and grades to meet all types of applications.

To accomplish a flush and smooth finish, use Neodymium Ring Magnet.

Our Bonded Neodymium Disc Magnets have thousands of uses in products from airbags and anti-lock brakes to medical instruments, credit card coding systems and toys.

Bonded Neodymium can be machined.

No matter the shape or size, we have the bonded magnet you need.

Blocks, rings or discs are all offered at great prices and a variety of sizes.

Bonded Neodymium can be easily machined.

Bonded Neodymium Magnets offer less flux than sintered magnets.

They can be formed into intricately shaped parts and do not suffer significant magnetic losses.

Our Ring-shaped magnets are used in many…

What are Neodymium Magnets?

Neodymium magnets are a member of the rare earth magnet family and are the most permanent magnets in the world.

They’re composed of Neodymium (Nd), Iron (Fe) and Boron (B), which makes them vulnerable to rust if they’re exposed to the elements.

To protect the magnet from corrosion and to strengthen the brittle magnet material, the magnet is usually coated with nickel.

High Heat and Neodymium Magnets

Like other rare earth magnets, neodymium magnets have a high resistance to demagnetization.

They will not lose their magnetization around other magnets, or if dropped.

However, neodymium magnets will completely lose their magnetization if heated above their Curie temperature, which is 590°F (310°C) for standard N grades.

offers a selection of neodymium disc magnets that are of high-temperature material, which can withstand higher temperatures without losing strength.

Neodymium magnets are available for standard temperature and high-temperature applications.

Standard temperature neodymium magnets will begin to lose strength if they are heated above their maximum operating temperature, which is 180°F (80°C).

High-temperature neodymium magnets can safely be used at operating temperatures up to 300° Fahrenheit (149° Celsius).

Neodymium magnets Applications

Neodymium magnets have a variety of uses, which makes perfect sense considering they’re extremely strong and affordable.

Here are just a few of the ways you’ll see neodymium magnets applied to everyday life:

Electronics — Cell phones, loudspeakers, headphones, and more everyday electronics use neodymium magnets.

Industrial applications — Alternators, flow meters, linear actuators, gyroscopes.

Clamps — A couple of neodymium blocks or cubes are perfect for holding pieces of metal in place.

This is most common when used for welding, drilling, or machining purposes.

Green Energy — Both hybrid and electric vehicles employ neodymium magnets, as do wind turbines.

Healthcare — Pacemakers and magnetic resonance imaging (MRI) machines use neodymium magnets.

Oil Filters — Ever wonder how metal chips are filtered out of oil? Neodymium magnets!

Stud Finders — These magnets are powerful enough to find hidden nails and other metal pieces inside walls.

Magnetic Therapy — For those who use magnetic therapy as a healing tool, neodymium magnets fit the bill perfectly.

There are different sized blocks to choose from depending on the size of the body being worked on.

Closers — Need to hold a brochure, box, binder, or other presentation piece shut? Neodymium magnets are perfect for the job.

Toys — You’ve probably played with magnets at some point in your life.

They were probably neodymium magnets! They’re used quite often as entertainment.

Remagnetization — Neodymium magnets can be used to put the magnetization back in other types of magnets, such as Alnico horseshoes and other bar magnets.

Metal Detectors — Did you know neodymium magnets are used in metal detectors?

Things to Know When Using Neodymium Magnets

If left exposed to the elements, the iron in the magnet will rust.

To protect the magnet from corrosion and to strengthen the brittle magnet material, we recommend coating the magnet in nickel plating.

Other coating options are zinc, tin, copper, epoxy, silver and gold.

Neodymium magnets must be handled with care to avoid injury and damage to you and the magnet.

Keep the following things in mind when handling neodymium magnets:

Fingers and hands can get severely pinched between two attracting magnets.

It is important that they are kept out of the reach of small children.

Neodymium magnets are brittle and can peel, crack or shatter if allowed to slam together.

Eye protection should be worn.

Neodymium magnets can also damage items such as credit cards, magnetic identification cards, or videotapes.

Never place neodymium magnets near electronic devices.

It is crucial to never allow them near a person with a pacemaker or similar medical aid.

Neodymium magnets should not be machined.

The material is brittle and prone to chipping and cracking, so it does not machine well by conventional methods.

Machining the magnets will generate heat, which if not carefully controlled, can demagnetize the magnet or even ignite the material which is toxic when burned.

Neodymium magnets: 5 mm x 2 mm x 0.5 mm N52, high grade, neodymium block. ALB Magnets 5 mm x 2 mm x 0.5 mm N52, high grade, neodymium block. Prices From: US0.08

They usually have a maximum operating temperature of 80℃ unless they are specifically made for a higher operating temperature.

The uses of Neodymium magnets are very varied but care must be taken because they are brittle, do not flex and may jump together and break!

Neodymium Magnets With Countersunk Holes

Neodymium Magnets 1 in x 1/2 in x 1/4 in Bar w/2 Dual Sided Countersunk Holes. Each hole is countersunk on both sides.

Make mounting Magnet Easier Using Neodymium Magnets With Countersunk Holes

All Countersunk Magnets Thicker Than 1/8" Are Countersunk On Both Sides Of The Magnet

$16.49

pull force: over 13 lbs Magnetized through thickness 1/4"

Price Range: $0.53 - $0.85

Work with #8 screws pull force: over 10 lbs Magnetized through thickness 1/8"

Price Range: $0.85 - $1.19

pull force: over 20 lbs Magnetized through thickness 1/4"

Price Range: $1.19 - $1.74

N45 magnets, stronger than N42 pull force: over 12 lbs Magnetized through thickness 1/8"

Price Range: $0.35 - $0.71

Pull force: over 11 lbs Magnetized through thickness 1/8"

Price Range: $0.52 - $0.89

Each hole is countersunk on both sides.

pull force: over 19 lbs Magnetized through thickness 1/4"

Price Range: $0.68 - $1.16

0.29-inch x 0.155 inches 82 degree countersunk hole on both sides.

pull force: over 19 lbs Magnetized through thickness 1/4"

Price Range: $0.79 - $1.19

Two countersunk holes on each magnet Each hole is countersunk on both sides N42 - Stronger than N40, N38 and N35 Pull Force: 37 lbs Magnetized through 1/2"

Price Range: $1.55 - $2.05

One countersunk hole on each magnet, center hole is countersunk on both sides N42 - Stronger than N40, N38 and N35 Pull Force: 37 lbs Magnetized through 1/2"

Price Range: $1.39 - $1.99

two countersunk holes on each magnet each hole is countersunk on both sides Magnetized through 3/16" Pull Force: 26 lbs

Price Range: $1.30 - $1.81

0.36x0.195" countersunk hole for #8 screw pull force: over 28 lbs Magnetized through thickness 1/4"

Price Range: $2.19 - $2.63

N45 magnets, stronger than N42 pulling force: over 55 lbs Magnetized through thickness 1/2"

Price Range: $3.68 - $4.85

pull force: over 24 lbs each hole is countersunk on both sides Magnetized through thickness 1/4"

Price Range: $1.36 - $2.09

Two countersunk holes on each magnet Each hole is countersunk on both sides Magnetized through 3/8" Pull Force: over 43 lbs

Price Range: $3.59 - $4.25

82 degree countersunk hole on both sides Fit with #6 screws pull force: over 28 lbs Magnetized through thickness 1/4"

Price Range: $2.35 - $3.15

Pull force: over 28 lbs Each hole is countersunk on both sides Magnetized through thickness 1/4"

Price Range: $2.05 - $3.19

Two 0.36x0.18" countersunk hole for #6/#8 screw pull force: over 46 lbs Magnetized through thickness 1/4"

Price Range: $5.29 - $6.40

N48 magnets, stronger than N45, N42

Two 0.365"x0.195" dual countersunk Holes for #8 screw pull force: over 54 lbs

Magnetized through thickness 1/4"

Best corrosion-resistant coating Epoxy + Nickel + Copper + Nickel 4-layer coating

Dual Sided Countersunk center hole fits with #6 metal screws

Grade N42, stronger than N40/N38/N35 Pull Force: 72 lbs

Hugh Piggott's Wind Generator

N42 magnets, stronger than N40, N38 Dual Sided Countersunk hole fits #8 metal screws Pull Force: over 72 lbs Hugh Piggott's wind turbine Magnetized through the 0.5"

Price Range: $5.30 - $6.35

N50 magnets, stronger than N48, N45, N42, N40, N38, and N35 Each hole is countersunk on both sides.

pull force: over 87 lbs Magnetized through thickness 1/2"

Price Range: $5.20 - $6.35

Dual Sided Countersunk hole works with #8/#10 screws N50 magnets, stronger than N48 Hugh Piggott's Wind Generator Pull Force: over 87 lbs Magnetized through 1/2

Price Range: $6.39 - $8.35

Grade N52 stronger than N50 Epoxy + Copper + Nickel 3-layer coating 82-degree Countersunk hole fits with #8 metal screw Hugh Piggott's Wind Generator Pull Force: 92 lbs Magnetized through 1/2

Price Range: $9.39 - $10.79

N42 magnets, stronger than N40 pull force: over 200 lbs 0.47"x0.195" countersunk hole Magnetized through thickness 1"

$30.99

N50 magnets, stronger than N48 pull force: over 250 lbs 0.365"x0.195" countersunk hole Magnetized through thickness 1"

Price Range: $27.99 - $35.35

N48 magnets, stronger than N45

pull force: over 35 lbs Magnetized through thickness 1/4"

Price Range: $3.79 - $4.39

Pull force: 3.5 lbs Magnetized through 1/8"

Price Range: $0.11 - $0.23

Pull force: 6.5 lbs Magnetized through 1/8" thickness

Price Range: $0.20 - $0.31

N48 magnets, stronger than N45, N42 Pull force: over 7 lbs Magnetized through 1/8" thickness

Price Range: $0.20 - $0.37

N45 magnets, stronger than N42 Pull force: 13 lbs Magnetized through 1/4" thickness

Price Range: $0.33 - $0.69

N42 magnets, stronger than N40, N38, N35 countersunk hole for #6 screws pulling force: over 6 lbs Magnetized through thickness 1/8"

Price Range: $0.82 - $1.24

N42 magnets, stronger than N40, N35

0.29x0.155" countersunk for #6 screws

pulling force: over 16 lbs

Work with #6 screws Pull force: 8.8 lbs Magnetized through 1/8" thickness

Price Range: $0.37 - $0.83

Pull force: over 10 lbs

Price Range: $0.59 - $0.88

N42 magnets, stronger than N35

0.29x0.155" countersunk for #6 screws

pulling force: over 18 lbs

Work with #8 screw Pull force: over 33 lbs Magnetized through thickness 1/2"

Price Range: $2.30 - $3.55

pull force: over 14 lbs Magnetized through thickness 1/8"

Price Range: $0.51 - $0.99

Strong N52 magnets, stronger than N50

pull force: over 17 lbs Magnetized through thickness 1/8"

Price Range: $0.73 - $1.26

pull force: over 16 lbs Magnetized through thickness 1/8"

Price Range: $0.84 - $1.09

The countersunk hole on one side of the magnet.

Fit #8 screw Pull force: over 18 lbs Magnetized through 3/16"

Price Range: $1.15 - $1.79

Pull force: 24 lbs Magnetized through 1/4"

Price Range: $1.29 - $1.79

Pull force: over 49 lbs Magnetized through thickness 1/2"

Price Range: $3.09 - $4.99

Pull force: over 69 lbs countersunk holes on both sides for #8 screw.

Magnetized through 3/8"

Price Range: $6.29 - $7.65

N42 Magnets, stronger than N40 Pull force: 115 lbs Magnetized through 1/2"

Price Range: $14.19 - $17.79

ALB Magnets offers the strongest magnets and neodymium magnets for sale at factory-direct prices.

We are a magnet wholesaler and retailer so when you buy from us you really are buying direct.

Through the sales volume we have built up over the years, we can offer you the highest quality magnets at the lowest prices.

Do not be fooled by our low prices on magnets and wind turbines.

These are factory direct prices.

We are committed to offering excellent performing, high-quality strong neodymium magnets & industrial magnets, flexible magnetic materials, ceramic magnetic materials, SmCo Samarium Cobalt magnetic materials, and AlNiCo magnetic materials.

MAGNETS ARE NOT TOYS! FOR ADULT USE ONLY!

To comply with 16 CFR Part 1240 - SAFETY STANDARD FOR MAGNET SETS

Our magnets are not intended for use with or as a magnet set.

A magnet set is defined as any aggregation of separable magnetic objects that is a consumer product intended, marketed or commonly used as a manipulative or construction items for entertainment, such as puzzle working, sculpture building, mental stimulation, or stress relief.

ALB Magnets is the #1 leading wholesaler of permanent rare earth industrial magnets, ferrite ceramic magnets, magnetic assemblies, magnet tools made with neodymium rare earth magnets, effective magnetic water treatment system made with the most powerful neodymium rare earth magnets and magnetic accessories and Magnetic Levitation Science Projects.

We distribute industrial neo-neodymium-iron-boron NdFeB rare earth magnets, cup magnets, samarium cobalt rare earth industrial magnets SmCo, ferrite (ceramic) magnets, magnetic strips, magnet wire, Magnetic Levitation & Magnetic Levitating Train Kits and magnetic tools.

This is a great new gadget we are carrying!

Works with all types of magnets!

How does it identify the north and south poles of a permanent magnet?

Simply press and hold the black oval button. Then, place the tip of the detector near the surface of the magnet.

If it is the North Pole, the Red LED will glow.

Magnet Pole Detector - Identifier-North

If it’s the South Pole, the Green LED will glow.

It’s just that simple.

And if the button is held and the unit is moved around the surface of the magnet….you can see the transition from one pole to another.

This pole identifier is guaranteed to be 100% accurate.

It can be used for NdFeB, SmCo, AlNiCo, Ceramic and most other magnets and refrigerator/flexible magnets.

Part of the content in this article is reproduced from other media for the purpose of transmitting more information and does not mean that this website agrees with its views or confirms the authenticity of its content. It shall not bear direct responsibility and joint liability for the infringement of such works.

If there is any infringement, bad information, error correction, and other issues in the content of this page, please contact us at info@albmaterials.com

Link to this article: https://www.albmagnets.com/blog/2-neodymium-magnets.html

How to choose and buy a strong neodymium magnet? ALBMagnets is a professional company for strong magnet design and manufacturing,

providing you with reliable N35, N38, N42, N52, N42SH and other grade super neodymium magnets and SmCo rare earth magnets.