By reducing reliance on fossil fuels and minimizing greenhouse gas emissions, electric vehicles equipped with neodymium magnet-based motors play a significant role in combating climate change and promoting environmental conservation.Neodymium Magnets play a crucial role in various components of electric motor vehicles (EMVs), contributing to their efficiency, performance, and overall functionality.

1. Role of Neodymium Magnets in Electric Vehicle Propulsion

In EV motors, Neodymium Magnets are typically integrated into the rotor assembly. When an electric current passes through the motor's coils, a magnetic field is generated, interacting with the magnetic field produced by the neodymium magnets. This interaction creates torque, which drives the rotation of the motor and ultimately propels the vehicle forward.

2. Advantages of Neodymium Magnets in Electric Vehicle Applications

The use of neodymium magnets in EV motors offers several advantages:

- Increased Power Density: Neodymium magnets contribute to higher power output and torque density, allowing for more efficient and powerful EV motors.

- Improved Efficiency: Neodymium magnets help minimize energy losses in EV motors, resulting in improved overall efficiency and longer driving range.

- Compact Design: The exceptional magnetic strength of neodymium magnets enables the creation of compact and lightweight EV motors without compromising performance.

- Enhanced Performance: Electric vehicles equipped with neodymium magnet-based motors exhibit superior acceleration, responsiveness, and overall performance compared to those using traditional magnet materials.

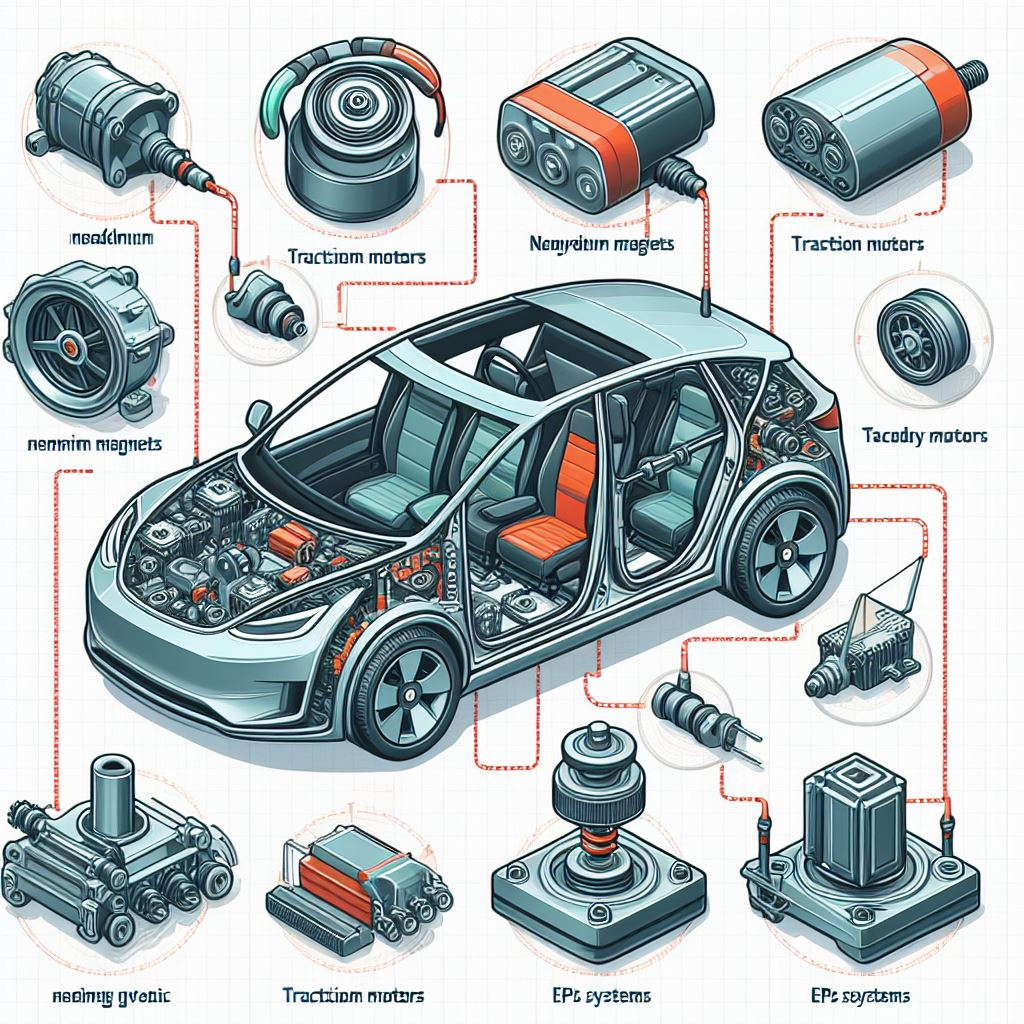

3. Ten applications of Neodymium Magnets in electric motor vehicles (EMVs):

Traction Motors: Neodymium Magnets are widely used in traction motors, which are the primary power source for propelling electric vehicles. These magnets generate the magnetic field necessary for motor operation, enabling efficient conversion of electrical energy into mechanical energy to drive the vehicle.

Electric Power Steering (EPS) Systems: Neodymium Magnets are employed in electric power steering systems to provide assistance to the driver in steering maneuvers. The magnets facilitate precise control and responsiveness, enhancing the driving experience while reducing energy consumption compared to traditional hydraulic systems.

Regenerative Braking Systems: Neodymium Magnets contribute to regenerative braking systems in electric vehicles, which harness kinetic energy during braking and convert it into electrical energy for storage in the vehicle's battery. This process improves energy efficiency and extends the vehicle's range.

Battery Management Systems (BMS): Neodymium Magnets are utilized in battery management systems to monitor and regulate the performance and state of charge of the vehicle's battery pack. These magnets enable the accurate detection of battery parameters, such as voltage, temperature, and current, ensuring safe and efficient battery operation.

Electric Air Conditioning Compressors: Neodymium Magnets are integrated into electric air conditioning compressors, which regulate the temperature inside electric vehicles. These magnets enable the efficient operation of the compressor, contributing to the vehicle's overall energy efficiency and comfort for passengers.

Electric Vehicle Charging Infrastructure: Neodymium Magnets are utilized in electric vehicle charging infrastructure, including electric vehicle supply equipment (EVSE) such as charging stations and plugs. These magnets facilitate the efficient transfer of electrical energy from the grid to the vehicle's battery, supporting the widespread adoption of electric vehicles.

Electric Powertrain Components: Neodymium Magnets are incorporated into various components of the electric powertrain, including inverters, converters, and motor controllers. These magnets enable the efficient conversion, control, and distribution of electrical power within the vehicle's propulsion system, optimizing performance and energy efficiency.

Electric Cooling Fans: Neodymium Magnets are employed in electric cooling fans used for thermal management in electric vehicles. These fans help dissipate heat generated by the vehicle's components, such as the battery pack and power electronics, ensuring optimal operating temperatures and prolonging the lifespan of critical systems.

Electric Brake Actuators: Neodymium Magnets are utilized in electric brake actuators, which control the braking force applied to the vehicle's wheels. These magnets enable precise and responsive brake actuation, enhancing safety and performance while reducing maintenance requirements compared to traditional hydraulic brake systems.

Electric Vehicle Motorsports: Neodymium Magnets are utilized in high-performance electric motorsports vehicles, including electric racing cars and motorcycles. These magnets provide the power and torque necessary for competitive racing, showcasing the capabilities of electric propulsion technology in demanding automotive environments.

Numerous electric vehicle manufacturers have adopted neodymium magnets in their motor systems to enhance performance and efficiency. For example, Tesla's Model S utilizes neodymium magnet-based motors, contributing to its impressive acceleration and range capabilities. Similarly, other electric vehicle models, including those from BMW, Nissan, and Chevrolet, leverage neodymium magnets to achieve optimal performance and energy efficiency.

Explore Our Neodymium Magnets

ALB Materials Inc is a leading manufacturer and wholesaler of Neodymium Magnets. Our extensive range of neodymium magnets, available in different grades, is utilized in various fields, including loudspeakers, wind turbines, mechanical devices, and medical equipment. We take pride in our competitive pricing, timely delivery, and exceptional customer service. For more information and to explore our products, visit our homepage.